Cartesian Gantry Robot

A Cartesian robot, also known as a Cartesian coordinate robot or linear robot, is a type of robotic arm that consists of three linear axes aligned with the X, Y, and Z Cartesian coordinate system. It operates by moving along these axes, which allows it to perform tasks such as pick and place, welding, assembly, and material handling.

XYCGT Series induced by closed loop stepper motor and controlled by integrated controller-driver TSC400. It is a 3 axes gantry system used for CNC machining, pick and place applications and assembly task. Servo cylinder actuators CGTH Series are used as single axis. 3 dimensional linear and arc interpolation used.

Features

- Coverage of Large Areas: Gantry robots can move along long spans, making them ideal for tasks over large surfaces or in large industrial settings.

- Accuracy in Positioning: High repeatability and precision make gantry robots perfect for applications like CNC machining, welding, and inspection.

- Smooth Movement: Linear guides and servomotors provide smooth and stable operation, ensuring consistent performance over long durations.

- Future-proof: These systems are adaptable to accommodate new technologies or modifications over time.

Specifications

X-Axis(CGTH8)

Repeatability (mm):±0.01

Ball Screw Lead (mm):10

Max. Speed (mm/sec):350

Stroke (50 increments) (mm):50~1100

AC Servo Output:42□ (48V)

Y-Axis(CGTH5)

Repeatability (mm):±0.01

Ball Screw Lead (mm):10

Max. Speed (mm/sec):538

Stroke (50 increments)(mm):50~400

AC Servo Output:42□ (48V)

Z-Axis(CGTH4)

Repeatability (mm):±0.01

Ball Screw Lead (mm):6

Max. Speed (mm/sec):314

Stroke (50 increments)(mm):50~100

AC Servo Output:35□ (48V)

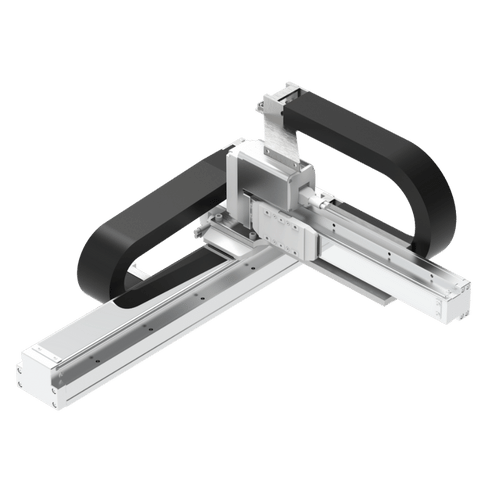

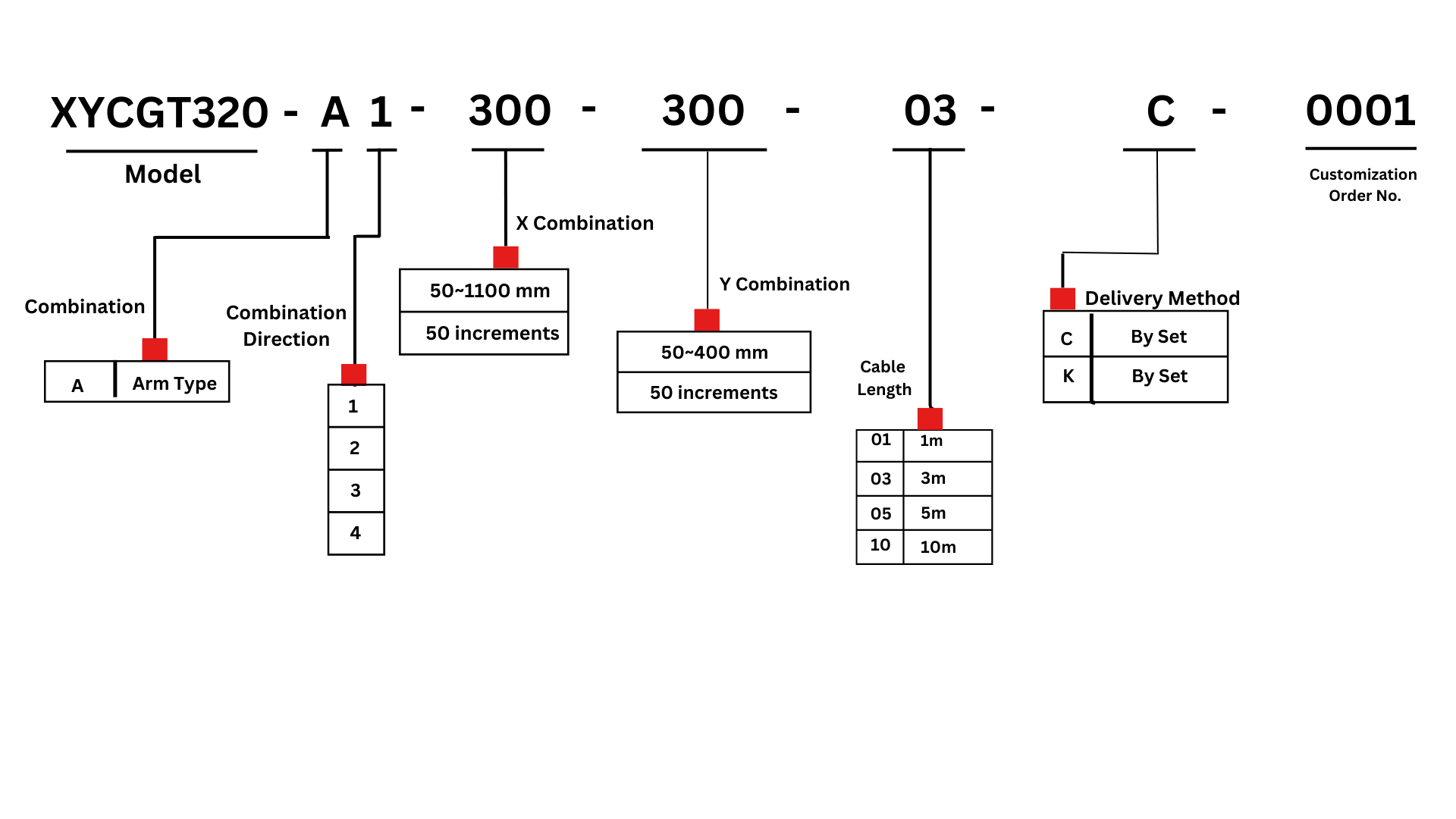

XYCGT320-A series

XYCGT32O-A series specification

| ITEM | X Axis | Y Axis | |

|---|---|---|---|

| Model Type | CGTH8 | CGTH5 | |

| Repeatability | mm | ±0.01 | ±0.01 |

| Ball Screw Lead | mm | 10 | 10 |

| Maximum Speed | mm/s | 350 | 538 |

| Stroke(50 increments) | mm | 50~1100 | 50~400 |

| AC Servo Motor Output | W | 42▢(48V) | |

| Environment | 0~40° C, 85% RH Below | ||

Maximum speed is based on the AC servo motor's 3000RPM.

| Maximum Payload | ||||||||

|---|---|---|---|---|---|---|---|---|

| Y Stroke(mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

| Y Payload | 5.5 Kg | |||||||

| Item | TSC400 Integrated Controller-driver Specification | |

|---|---|---|

| Driver Method | Closed-loop stepper method | |

| Control method | Point-to-point(PTP), Continuous path (CP) | |

| Interpolation | 3-dimensonal linear and arc interpolation | |

| Teaching Method | Remote Teaching(JOG)/Manual Data Input(MDI) | |

| Teaching System | PC-based UI: Convert 2D CAD files to paths;import images for tracing. | |

| PAD-based UI: teach position, edit programs. | ||

| UI | Languages | Chinese(Traditional), English, Japanese |

| Units | mm | |

| Programs Capacity | 100 programs (1~100) | |

| Data Capacity | Up to 100,000 points | |

| Simple PLC Function | 100 sets, Up to 1,000 steps | |

| External Input/Output | IO | 16 IN/16 OUT (NPN/PNP) |

| LAN | Ethernet need to use under TOYO UI(Through the hub to devices) | |

| COM | RS-232C(Supports peripheral device connections) | |

| USB | Firmware Updates, Procedure Import/Export | Power Source | AC-100~240, 5A |

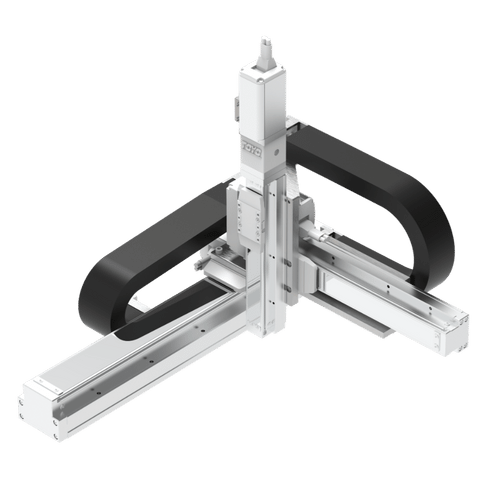

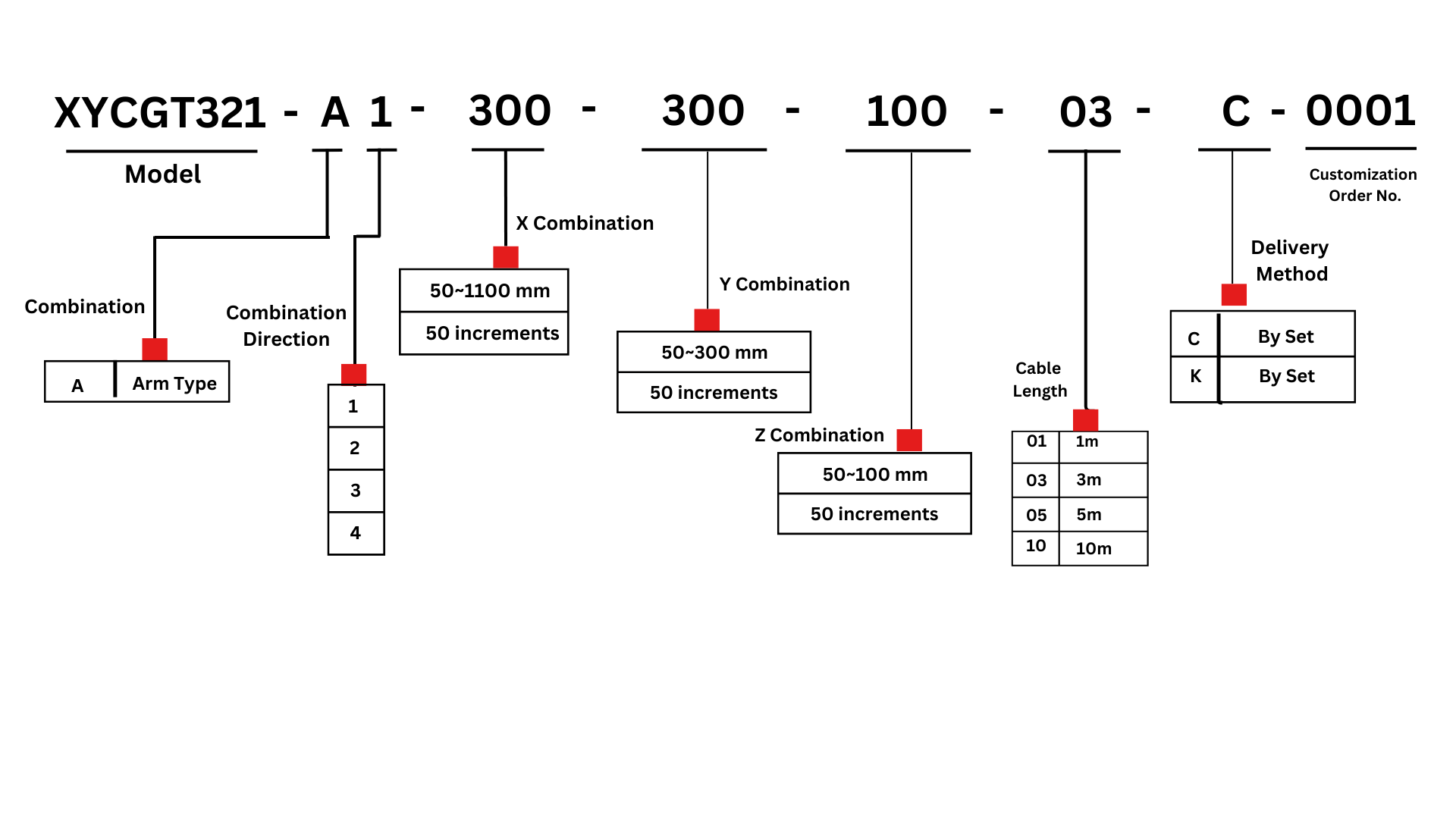

XYCGT321-A series

XYCGT321-A series specification

| ITEM | X Axis | Y Axis | Z Axis | |

|---|---|---|---|---|

| Model Type | CGTH8 | CGTH5 | CGTH4 | |

| Repeatability | mm | ±0.01 | ±0.01 | ±0.01 |

| Ball Screw Lead | mm | 10 | 10 | 6 |

| Maximum Speed | mm/s | 350 | 538 | 314 |

| Stroke(50 increments) | mm | 50~1100 | 50~300 | 50~100 |

| AC Servo Motor Output | W | 42▢(48V) | 42▢(48V) | 35▢+Brake(48V) |

| Environment | 0~40° C, 85% RH Below | |||

Maximum speed is based on the AC servo motor's 3000RPM.

| Maximum Payload | ||||||

|---|---|---|---|---|---|---|

| Y Stroke(mm) → | 50 | 100 | 150 | 200 | 250 | 300 |

| Z Stroke(mm) ↓ | ||||||

| 50 | 5 KG | |||||

| 100 | ||||||

| Item | TSC400 Integrated Controller-driver Specification | |

|---|---|---|

| Driver Method | Closed-loop stepper method | |

| Control method | Point-to-point(PTP), Continuous path (CP) | |

| Interpolation | 3-dimensonal linear and arc interpolation | |

| Teaching Method | Remote Teaching(JOG)/Manual Data Input(MDI) | |

| Teaching System | PC-based UI: Convert 2D CAD files to paths;import images for tracing. | |

| PAD-based UI: teach position, edit programs. | ||

| UI | Languages | Chinese(Traditional), English, Japanese |

| Units | mm | |

| Programs Capacity | 100 programs (1~100) | |

| Data Capacity | Up to 100,000 points | |

| Simple PLC Function | 100 sets, Up to 1,000 steps | |

| External Input/Output | IO | 16 IN/16 OUT (NPN/PNP) |

| LAN | Ethernet need to use under TOYO UI(Through the hub to devices) | |

| COM | RS-232C(Supports peripheral device connections) | |

| USB | Firmware Updates, Procedure Import/Export | Power Source | AC-100~240, 5A |