Cartesian Gantry System

A gantry system is a specific type of Cartesian robot, characterized by its large-scale, overhead structure. It consists of a framework where the robotic arms or tools are mounted on a movable bridge, allowing for controlled motion over large areas. All the actuators used for X,Y and Z are ball screw driven. Gantry system are widely used in industries such as electronics manufacturing, automotive, and pharmaceuticals, where repeatable precision is crucial.

XYSGT Series induced by servo motor and controlled by integrated controller-driver TSC400. Servo cylinder actuators SGTH Series are used as single axis. 3 dimensional linear and arc interpolation used. Upto 100 programs can be set.

Features

- Three-Axis (X, Y, Z) Movement: Like Cartesian robots, gantry systems offer precise control along three orthogonal axes, often with additional rotational axes if needed.

- Customizable Setup: Gantry systems are modular, meaning the tracks and axes can be extended, shortened, or adjusted to suit specific tasks or industries.

- Flexible Integration: Can be combined with vision systems, tooling, and other robotic systems for complex automation processes.

- Multi-tasking Capability: Gantry systems can often support multiple tools or functions simultaneously, maximizing productivity.

Specifications

X-Axis(SGTH12)

Repeatability (mm):±0.005

Ball Screw Lead (mm):20

Max. Speed (mm/sec):1000

Stroke (50 increments) (mm):50~1250

AC Servo Output:400W

Y-Axis(SGTH8)

Repeatability (mm):±0.005

Ball Screw Lead (mm):20

Max. Speed (mm/sec):1000

Stroke (50 increments)(mm):50~450

AC Servo Output:200W

Z-Axis(SGTH5)

Repeatability (mm):±0.005

Ball Screw Lead (mm):5

Max. Speed (mm/sec):250

Stroke (50 increments)(mm):50~100

AC Servo Output:1000W+Brake

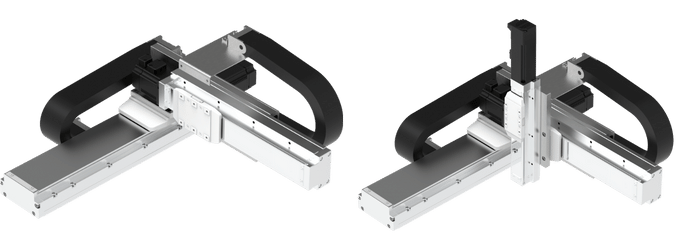

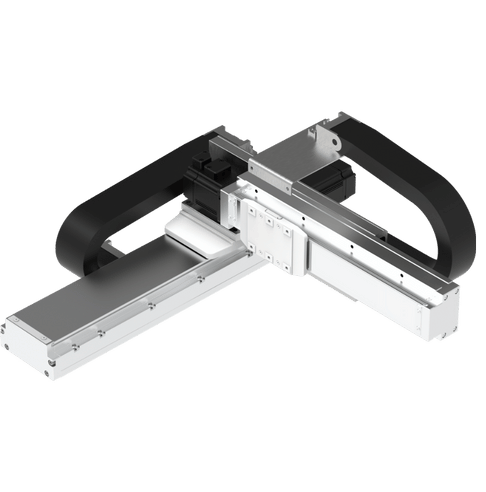

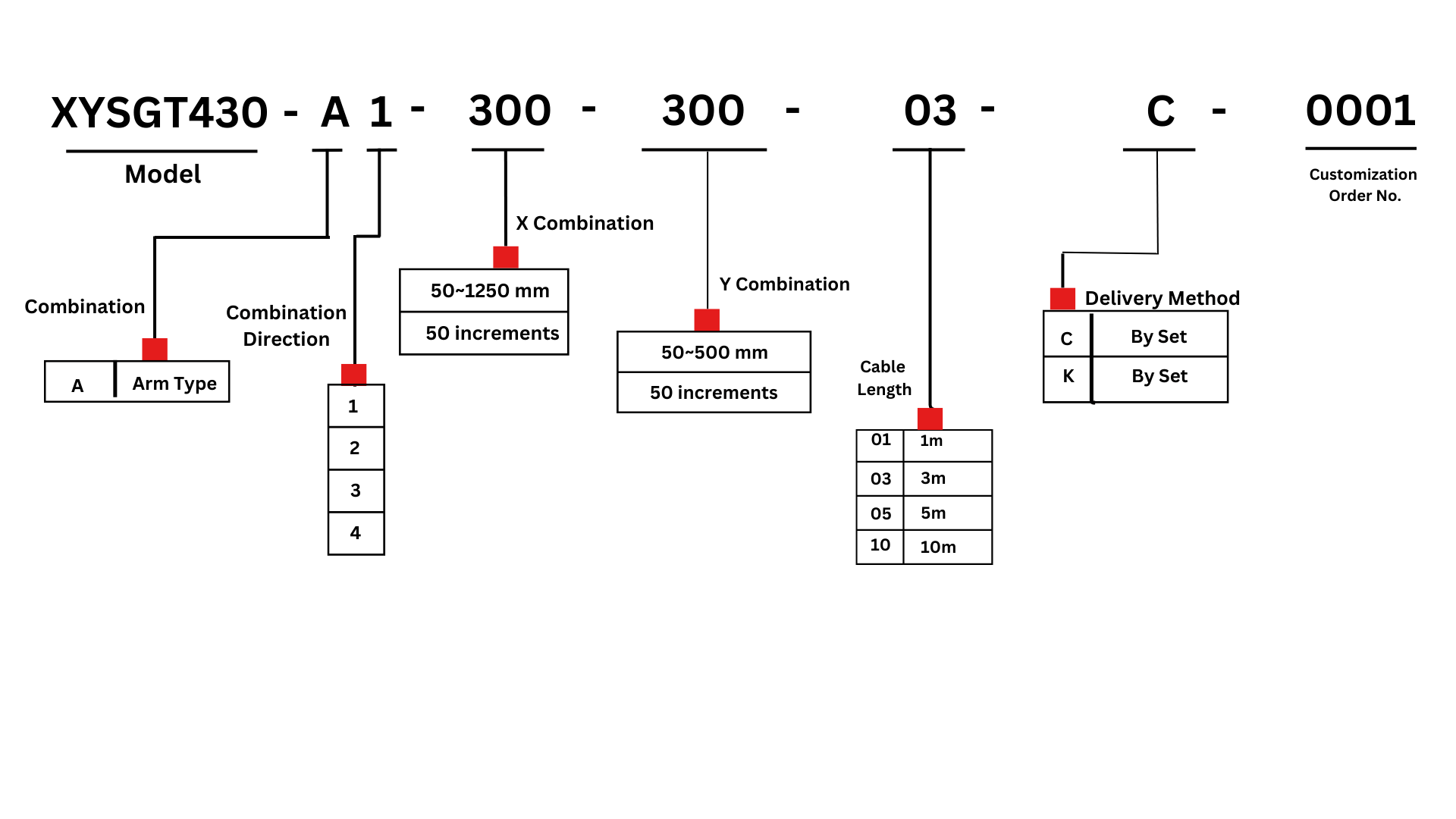

XYSGT430-A series

XYCGT43O-A series specification

| ITEM | X Axis | Y Axis | |

|---|---|---|---|

| Model Type | SGTH12 | SGTH8 | |

| Repeatability | mm | ±0.005 | ±0.005 |

| Ball Screw Lead | mm | 20 | 20 |

| Maximum Speed | mm/s | 1000 | 1000 |

| Stroke(50 increments) | mm | 50~1250 | 50~500 |

| AC Servo Motor Output | W | 400W | 200W |

| Environment | 0~40° C, 85% RH Below | ||

Maximum speed is based on the AC servo motor's 3000RPM.

| Maximum Payload | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Y Stroke(mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| Y Payload | 12 Kg | |||||||||

| Item | TSC400 Integrated Controller-driver Specification | |

|---|---|---|

| Driver Method | Servo Motor | |

| Control method | Point-to-point(PTP), Continuous path (CP) | |

| Interpolation | 3-dimensonal linear and arc interpolation | |

| Teaching Method | Remote Teaching(JOG)/Manual Data Input(MDI) | |

| Teaching System | PC-based UI: Convert 2D CAD files to paths;import images for tracing. | |

| PAD-based UI: teach position, edit programs. | ||

| UI | Languages | Chinese(Traditional), English, Japanese |

| Units | mm | |

| Programs Capacity | 100 programs (1~100) | |

| Data Capacity | Up to 100,000 points | |

| Simple PLC Function | 100 sets, Up to 1,000 steps | |

| External Input/Output | IO | 16 IN/16 OUT (NPN/PNP) |

| LAN | Ethernet need to use under TOYO UI(Through the hub to devices) | |

| COM | RS-232C(Supports peripheral device connections) | |

| USB | Firmware Updates, Procedure Import/Export | Power Source | AC-220~240V, 15A |

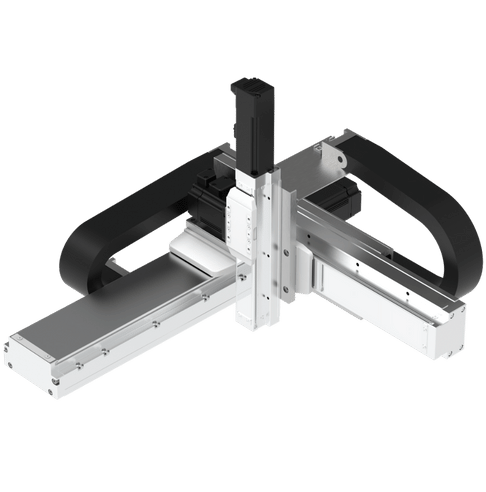

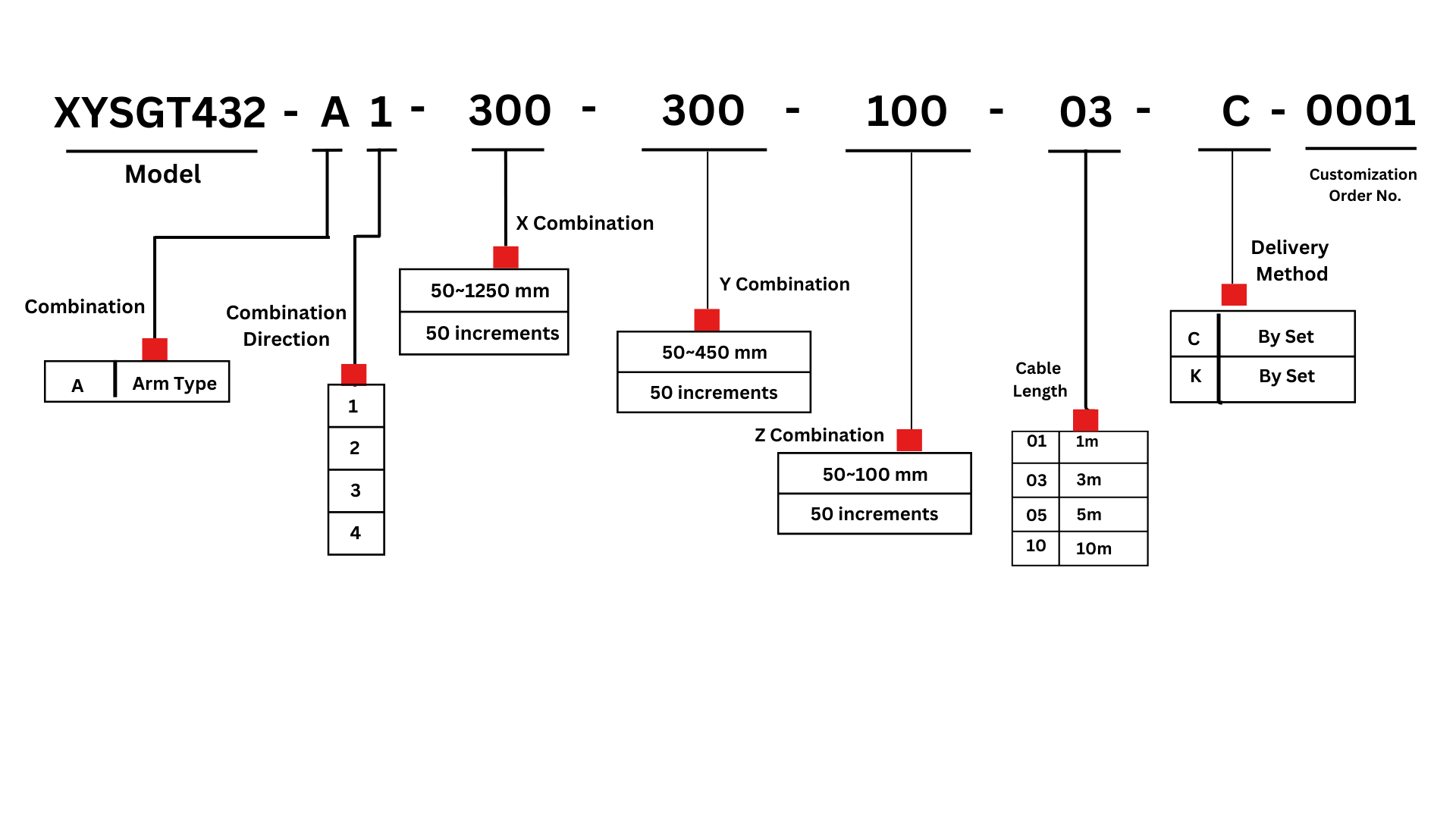

XYSGT432-A series

XYSGT432-A series specification

| ITEM | X Axis | Y Axis | Z Axis | |

|---|---|---|---|---|

| Model Type | SGTH12 | SGTH8 | SGTH5 | |

| Repeatability | mm | ±0.005 | ±0.005 | ±0.005 |

| Ball Screw Lead | mm | 20 | 20 | 5 |

| Maximum Speed | mm/s | 1000 | 1000 | 250 |

| Stroke(50 increments) | mm | 50~1250 | 50~450 | 50~100 |

| AC Servo Motor Output | W | 400W | 200W | 100W+Brake |

| Environment | 0~40° C, 85% RH Below | |||

Maximum speed is based on the AC servo motor's 3000RPM.

| Maximum Payload | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Y Stroke(mm) → | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 |

| Z Stroke(mm) ↓ | |||||||||

| 50 | 10 KG | ||||||||

| 100 | |||||||||

| Item | TSC400 Integrated Controller-driver Specification | |

|---|---|---|

| Driver Method | Closed-loop stepper method | |

| Control method | Point-to-point(PTP), Continuous path (CP) | |

| Interpolation | 3-dimensonal linear and arc interpolation | |

| Teaching Method | Remote Teaching(JOG)/Manual Data Input(MDI) | |

| Teaching System | PC-based UI: Convert 2D CAD files to paths;import images for tracing. | |

| PAD-based UI: teach position, edit programs. | ||

| UI | Languages | Chinese(Traditional), English, Japanese |

| Units | mm | |

| Programs Capacity | 100 programs (1~100) | |

| Data Capacity | Up to 100,000 points | |

| Simple PLC Function | 100 sets, Up to 1,000 steps | |

| External Input/Output | IO | 16 IN/16 OUT (NPN/PNP) |

| LAN | Ethernet need to use under TOYO UI(Through the hub to devices) | |

| COM | RS-232C(Supports peripheral device connections) | |

| USB | Firmware Updates, Procedure Import/Export | Power Source | AC-100~240, 5A |