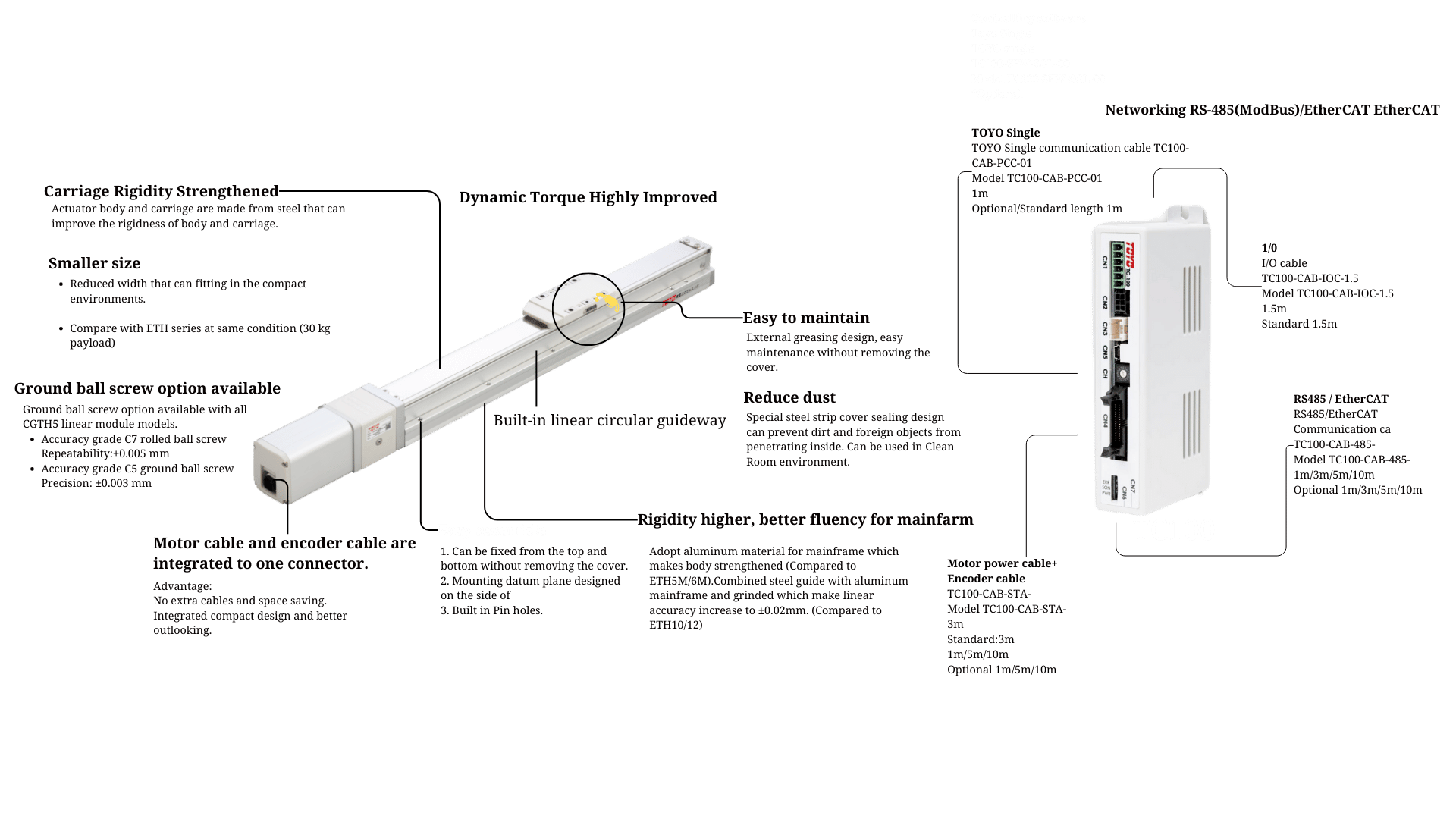

Integrated Linear Bearings Servo Cylinder - Slider type

These are the actuators which convert rotary motion into precise linear motion hence they called servo cylinder. They induce or control motion in mechanical device. CGTH series of linear actuator operated by closed loop stepper motor. Closed loop type stepper motor is used to incorporate positional feedback in order to control rotational or linear speed and position. Toyo provide these types of linear actuators along with its motor. We provide a combine solution, the controller for these actuators is also can be availed by us.

Closed-loop stepper motors have an encoder or other feedback device that constantly monitors the motor's position so when you need variation in speed of actuator for certain station of its journey, you can control actuator’s movements with the help of controller and encoder.

CGTH Series is a ball screw type actuator which comes with integrated linear bearings. The with motor solution deducts your selection process of motor.

Features

- Position control: Accurate control over the actuator’s movement through precise feedback and positioning.

- Velocity control: Control over the speed of the cylinder's movement.

- Feedback mechanism:Sensors monitor the actuator’s position and velocity, allowing for real-time monitoring and adjustments.

- Double-acting: The actuators can move in both directions, allowing bi-directional motion.

- High-precision: Servo cylinders are designed for high-precision applications, making them suitable for industries such as robotics and aerospace.

- Standard Controller:Standard controller also provides PULSE, communication and other two control interfaces and can be equipped with CAN Open and EtherCAT networks.

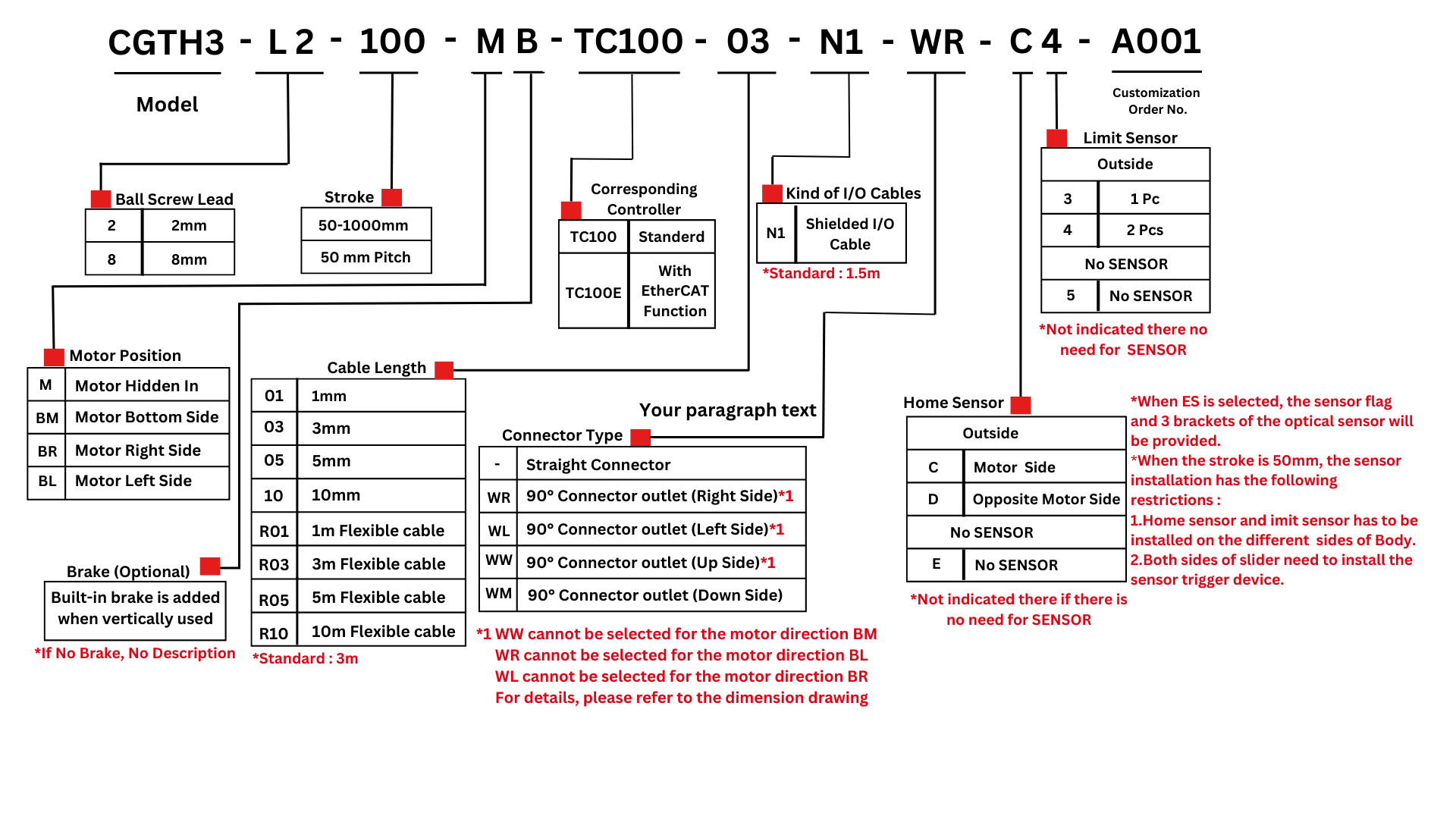

CGTH3 series

CGTH3 series specification

| Specification | Repeatability | mm | ±0.005 | ||

|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 8 | ||

| Minumum Rotating Speed | rpm | ≤3000 | ≤3000 | ||

| Maximum Speed | Horizontal(kg) | mm/s | ≤100 | ≤400 | |

| Vertical(kg) | mm/s | ≤13 | ≤10 | ||

| Rated Thurst | N | 373 | 93 | ||

| Stroke Increments | mm | 50-500mm/50 increments | |||

| Motor Dimension | mm | 25 | |||

| Ball Screw Spec. | mm | C7 ⌀6mm | |||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

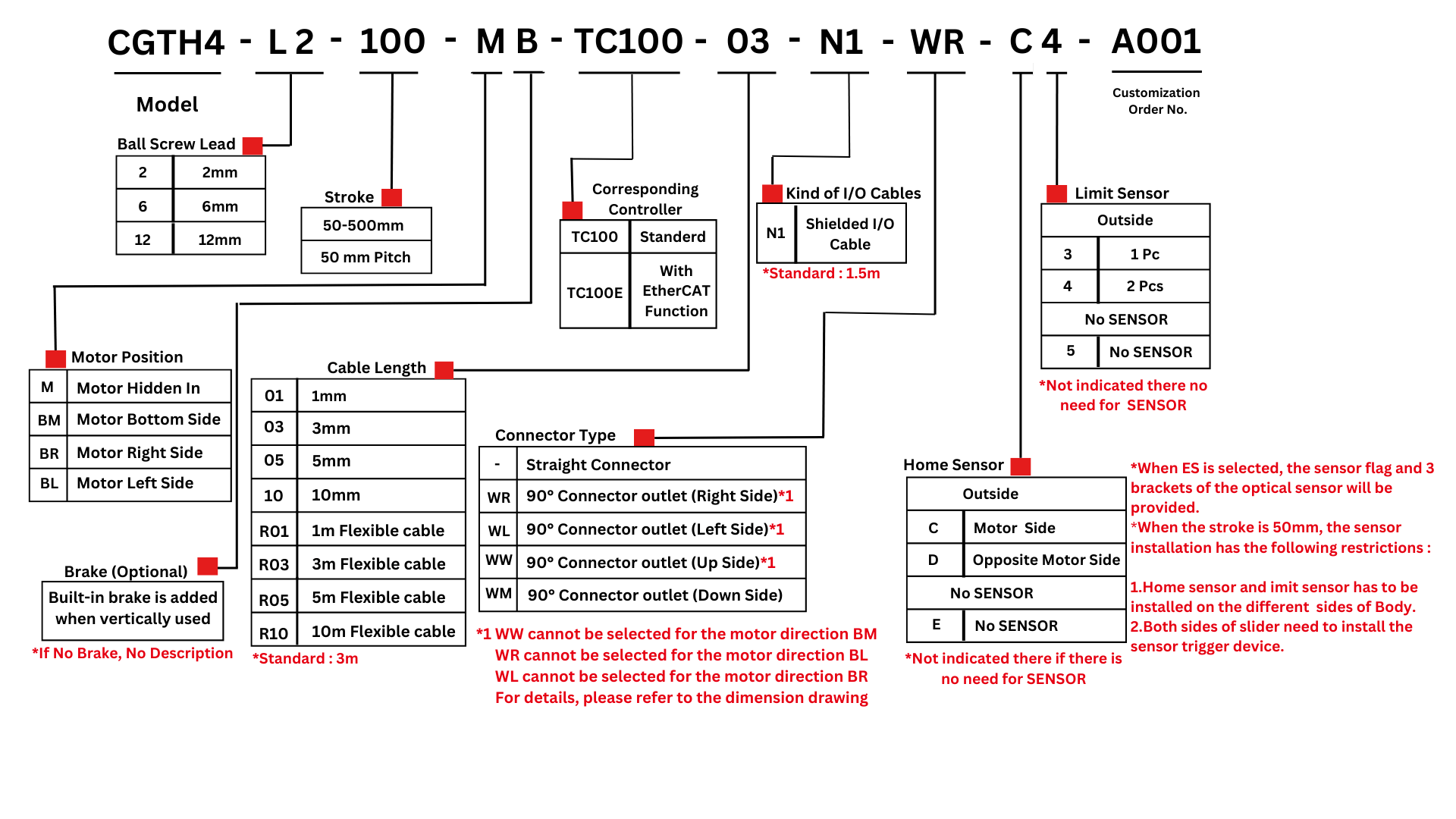

CGTH4 series

CGTH4 series specification

| Specification | Repeatability | mm | ±0.005 | |||

|---|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 6 | 12 | ||

| Minumum Rotating Speed | rpm | ≤3000 | ≤3000 | ≤3000 | ||

| Maximum Speed | Horizontal(kg) | mm/s | ≤100 | ≤300 | ≤600 | |

| Vertical(kg) | mm/s | ≤100 | ≤300 | ≤600 | ||

| Maximum Payload | Horizontal | (kg) | ≤25 | ≤20 | ≤12 | |

| Vertical | kg | ≤8 | ≤8 | ≤3.5 | ||

| Rated Thurst | N | 1094 | 365 | 182 | ||

| Stroke Increments | mm | 50-1000mm/50 increments | ||||

| Motor Dimension | mm | 35 | ||||

| Ball Screw Spec. | mm | C7 ⌀10mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

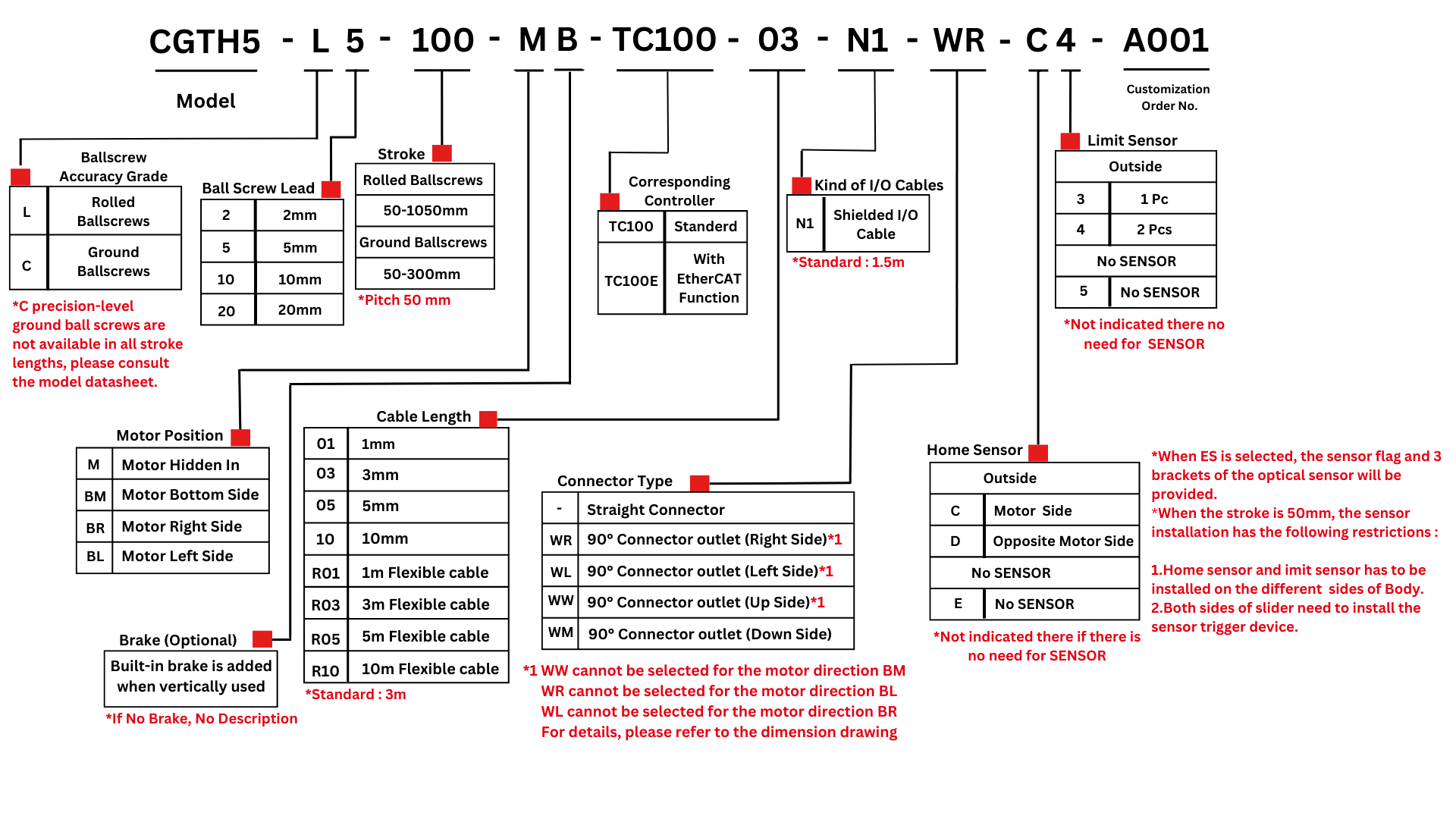

CGTH5 series

CGTH5 series specification

| Specification | Ballscrew Accuracy Grade Code | L | C | |||

|---|---|---|---|---|---|---|

| BallScrew Accuracy Grade | C7(Rolled ballscrews) | C5(Ground ballscrews) | ||||

| Repeatability(mm) | ±0.005 | ±0.003 | ||||

| Stroke Pitch | 50-1050mm/50 pitch | 50-300mm/50 pitch | ||||

| Ball Screw Lead(mm) | 2 | 5 | 10 | 20 | ||

| Maximum Rotating Speed(rpm) | ≤3000 | ≤3000 | ≤3000 | ≤3000 | ||

| Maximum Speed(mm/s) | Horizontal(kg) | ≤100 | ≤250 | ≤500 | ≤1000 | |

| Vertical(kg) | ≤100 | ≤250 | ≤500 | ≤1000 | ||

| Maximum Payload(kg) | Horizontal | ≤30 | ≤30 | ≤15 | ≤10 | |

| Vertical(kg) | ≤10 | ≤10 | ≤5 | ≤2.5 | ||

| Rated Thurst(N) | 1147 | 459 | 229 | 115 | ||

| Motor Dimension(mm) | 42 | |||||

| Ball Screw Spec. | ⌀12mm | |||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

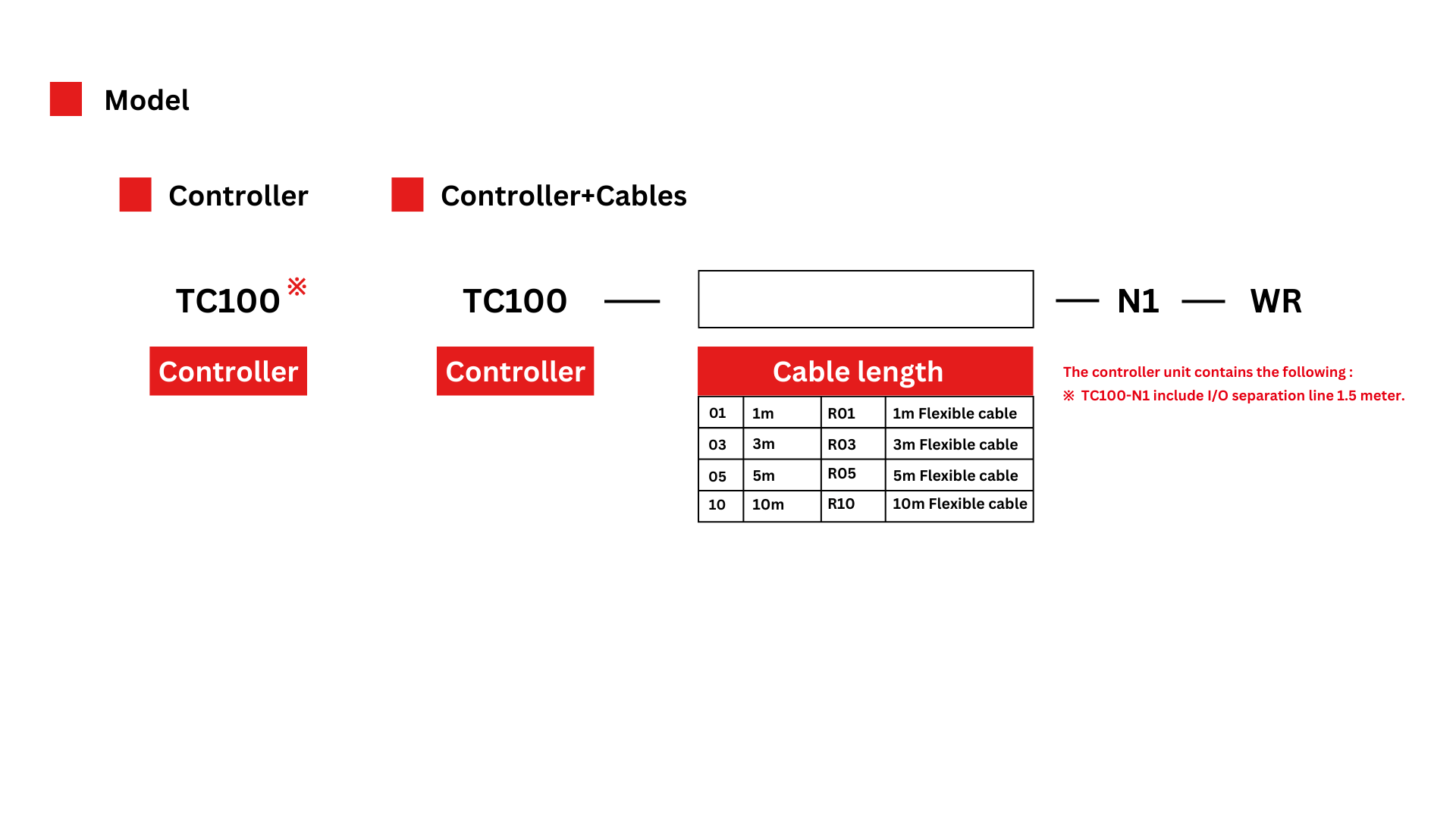

TC100

TC100 Controller specification

| ITEM | Specification | ||

|---|---|---|---|

| Input Power | Control Power | DC 24V(±10%) | |

| Power Supply | DC 24V(±10%)/DC 48V(±10%) | ||

| Number of Controlled Axis | 1 single axis | ||

| Motor | Appropriate Motor | Two phase stepping motor | |

| Dimension | 36` 42` 35` 25` 20 | ||

| Rated Output | 2Ao-p Peak value of sine wave current | ||

| Instant Maximum Output | 3Ao-p Peak value of sine wave current | ||

| Motion Control Mode | ABS Mode | ||

| INC Mode | |||

| INC-R Continuous Mode | |||

| ABS-R Continuous Mode | |||

| TSL Thurst Mode | |||

| Position | Total number of points | 1~127 points | |

| Position Setting Method | Communication setting point position | ||

| I/O point position teaching | |||

| Encoder | Position Mangement | Incremental | |

| Positiion Checking | Optical Rotary Encoder | ||

| Resolution | 16000ppr(56`42 angles)/12800ppr(35 angles)/9600ppr(25 angles)/1600ppr(20 angles) | ||

| General DI/DO Signal | DI(14 points)/DO(10 points) NPN modify definition through parameter | ||

| Brake | Optional(please inform before buying) | ||

| Error History | Maximum storage for 50 error code | ||

| Safety Circuit | Emergency stop switch(servo OFF)Emergency stop switch(servo OFF) | ||

| Communication | USB(virtual COM port):Mini USB/RS485(half duplex):RJ-45/EtherCAT | ||

| LED LED Status Desplay |

PWR: power supply(green)permanent radiating when drive + control power supply input, green flashing when the drive power supply was turned off | ||

| SON: servo(green): permanent radiating when servo ON, extingushed when the error shows | |||

| ERR: error(red); use the times of flashing to decide the error messages. | |||

| Station number setting | Rotating DIP switch (0~f), 16 station | ||