Linear Motor Actuator

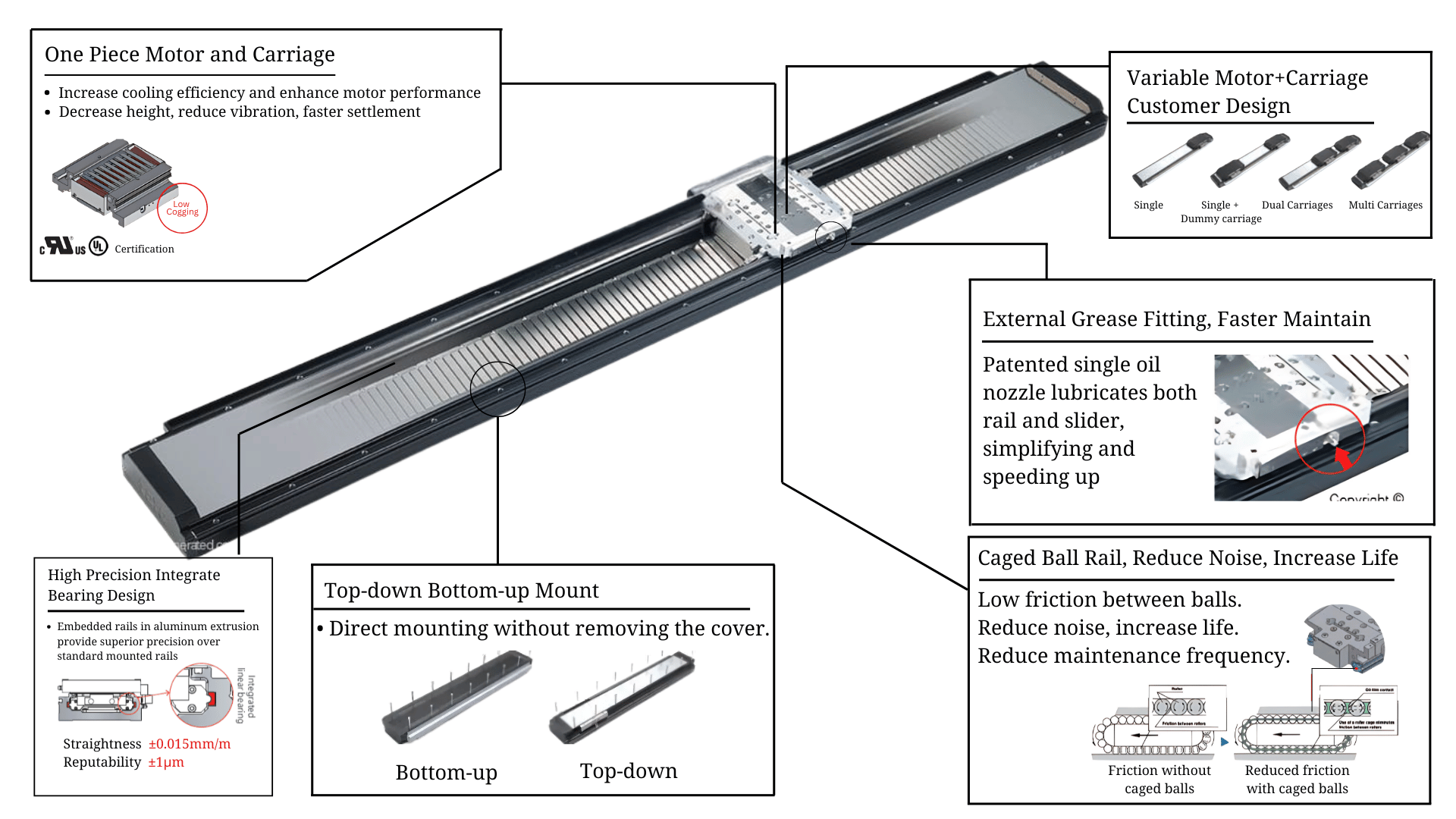

Linear motor actuators use an electromagnetic drive system for smooth, accurate, and high-speed motion. Cogging-free operation in ironless designs ensures ultra-smooth motion, even at low speeds. Suited for precision applications like photonics, semiconductor processing, and biomedical systems. LGW series of linear motor actuator are designed for small, low profile, Low vibration, High payload, Accurate and Speedy application. Its bigger rail spacing increases moment load capacity and payload. Due to its Shorter Carriage, strokes become Longer and Effective.

Patented single oil nozzle lubricates both rail and slider, simplifying and speeding up maintenance. Caged Ball rail reduces noise and increases life. LGTW, LGNW and LGCW are subtypes of LGW series from LGCW is a cleanroom actuator with its external suction it can reach CLASS 100 cleanroom standard. LGTW and LGNW are standard type with integrate bearing linear motor module.

Features

- These LGW linear actuator are ready for semiconductor manufacturing process automation.

- Flexible option of gear head from 1~0.1μm

- The external greasing fitting eases maintenance and increase its life.

- Caged ball rail reduces noise.

- Maximum acceleration can be upto 2500 mm/s.

- One piece motor and carriage increase cooling efficiency and enhance motor performance.

- These actuators can be directly mounted without removing cover.

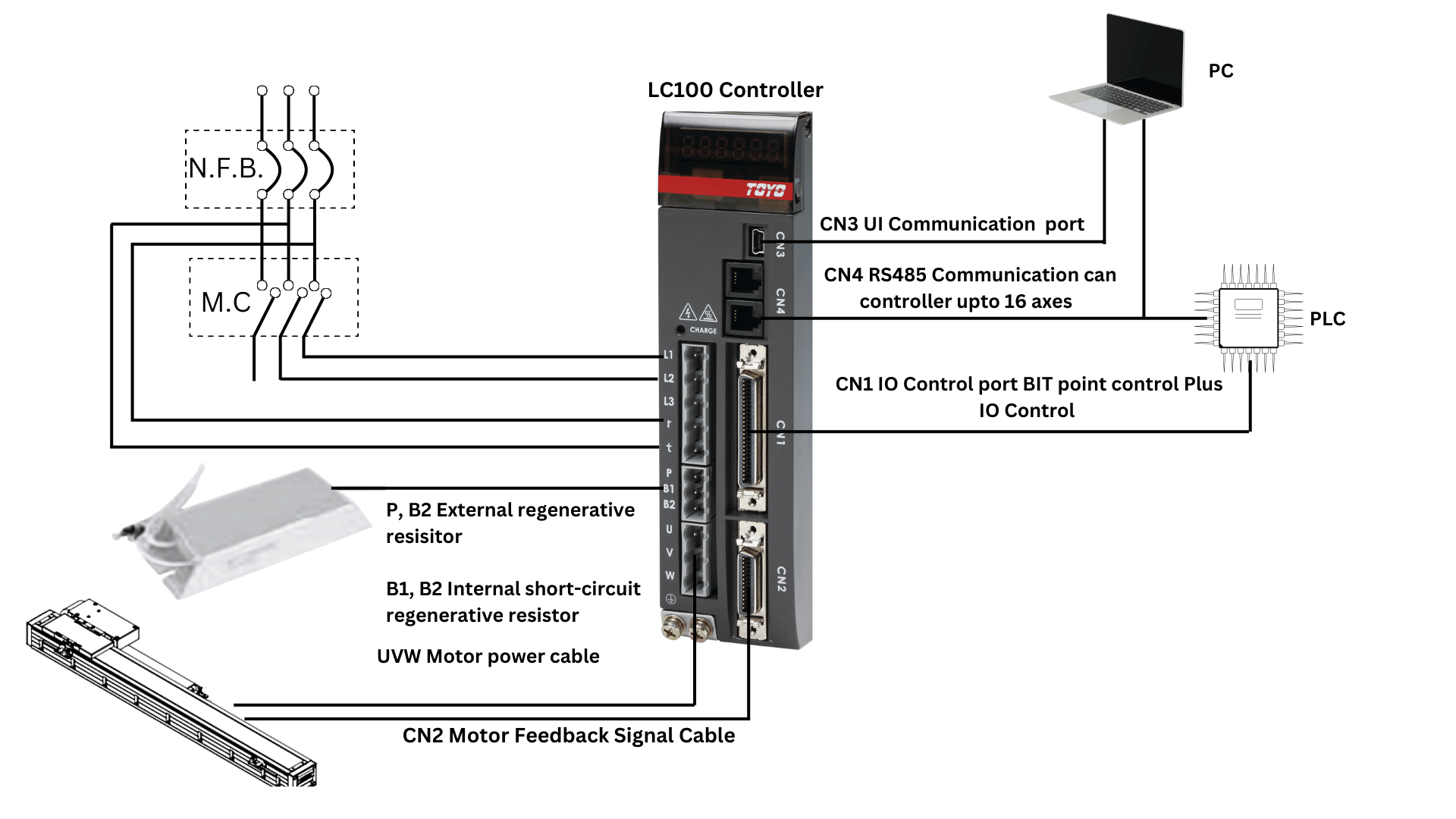

- LC100 controller is used to for control via IO control of main controller (PLC), communication control and pulse control.

Applications

Spray printing device for PCB board, Aligning device for pick and place of IC boards, Barcode scanning device

Industries

TFT Display manufacturing, Food industry, Packing machinery, LED manufacturing, CNC machining, Textile machinery, Printing and labelling, Laboratory automation, Material handling.

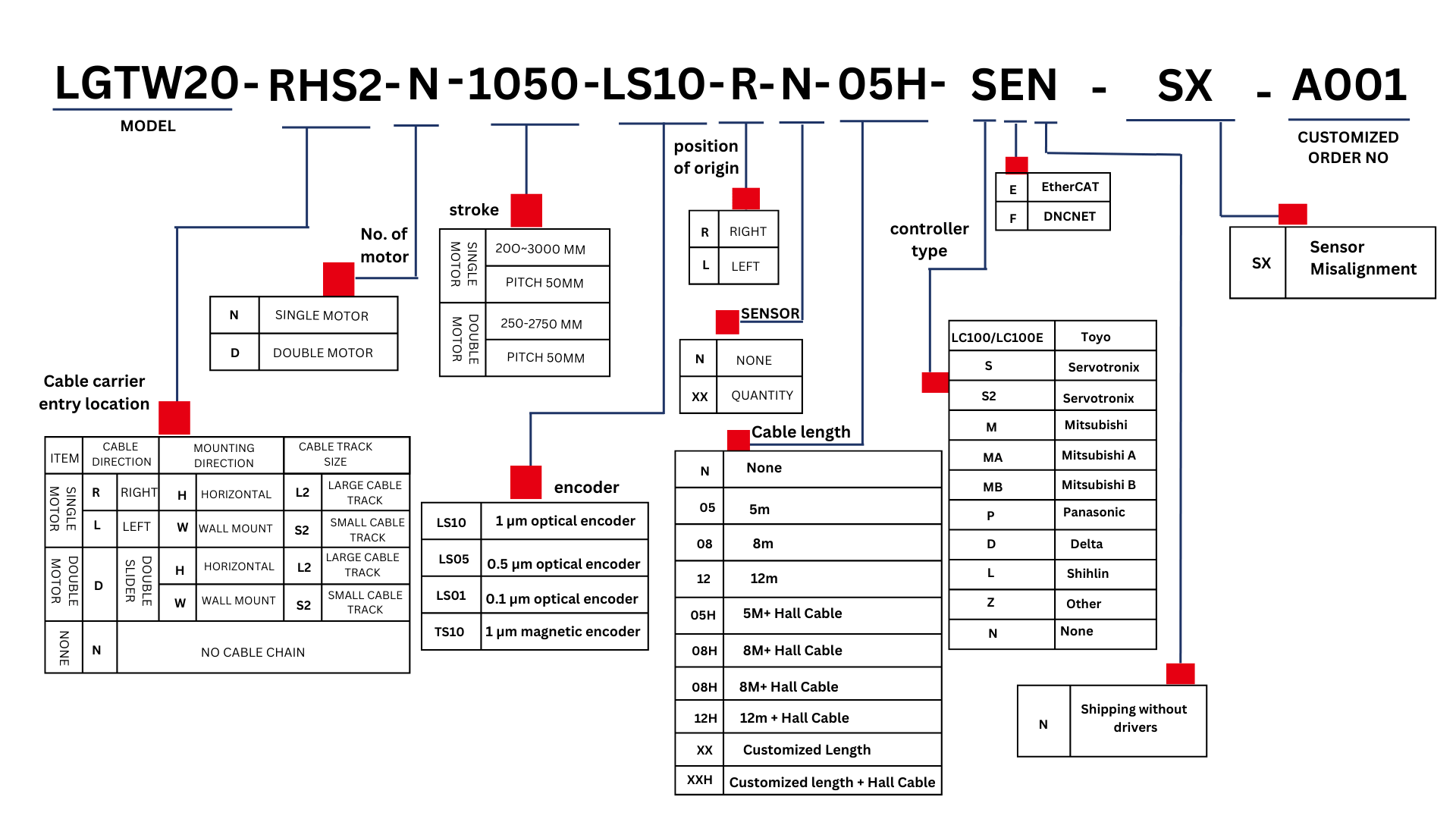

LGTW20 series

LGTW20 series specification

| Performance | Model | LGTW20 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 432 | |||

| Rated Force | N | 136.7 | |||

| Maximum Payload | Kg | 20 | 9 | ||

| Stroke | mm | 200~3000/50 pitch | 200~3000/50 pitch | ||

| mm | 250~2750/50 pitch | 250~2750/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

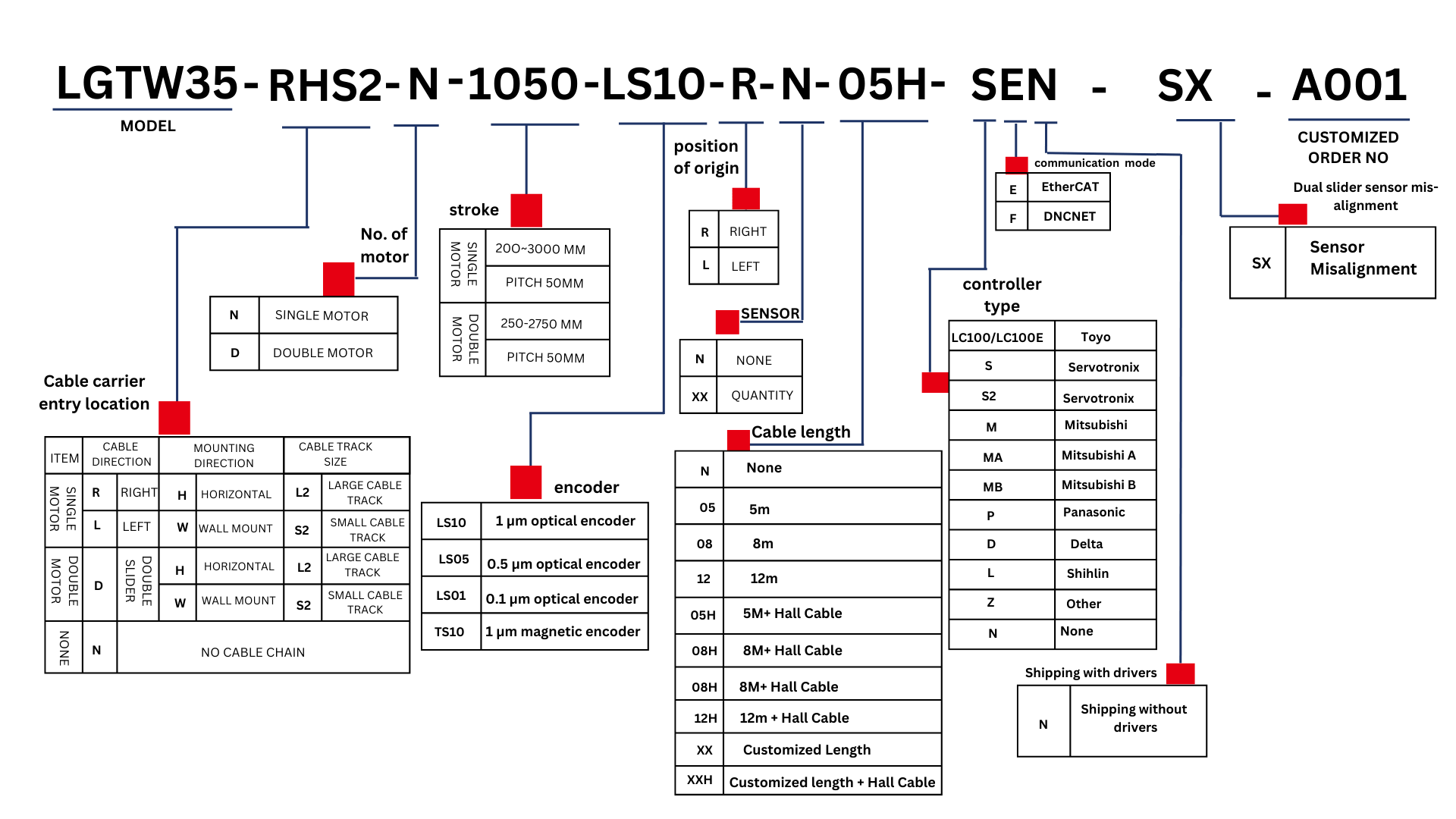

LGTW35 series

LGTW35 series specification

| Performance | Model | LGTW35 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 760 | |||

| Rated Force | N | 251 | |||

| Maximum Payload | Kg | 35 | 12 | ||

| Stroke | mm | 200~3000/50 pitch | 200~3000/50 pitch | ||

| mm | 250~2750/50 pitch | 250~2750/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

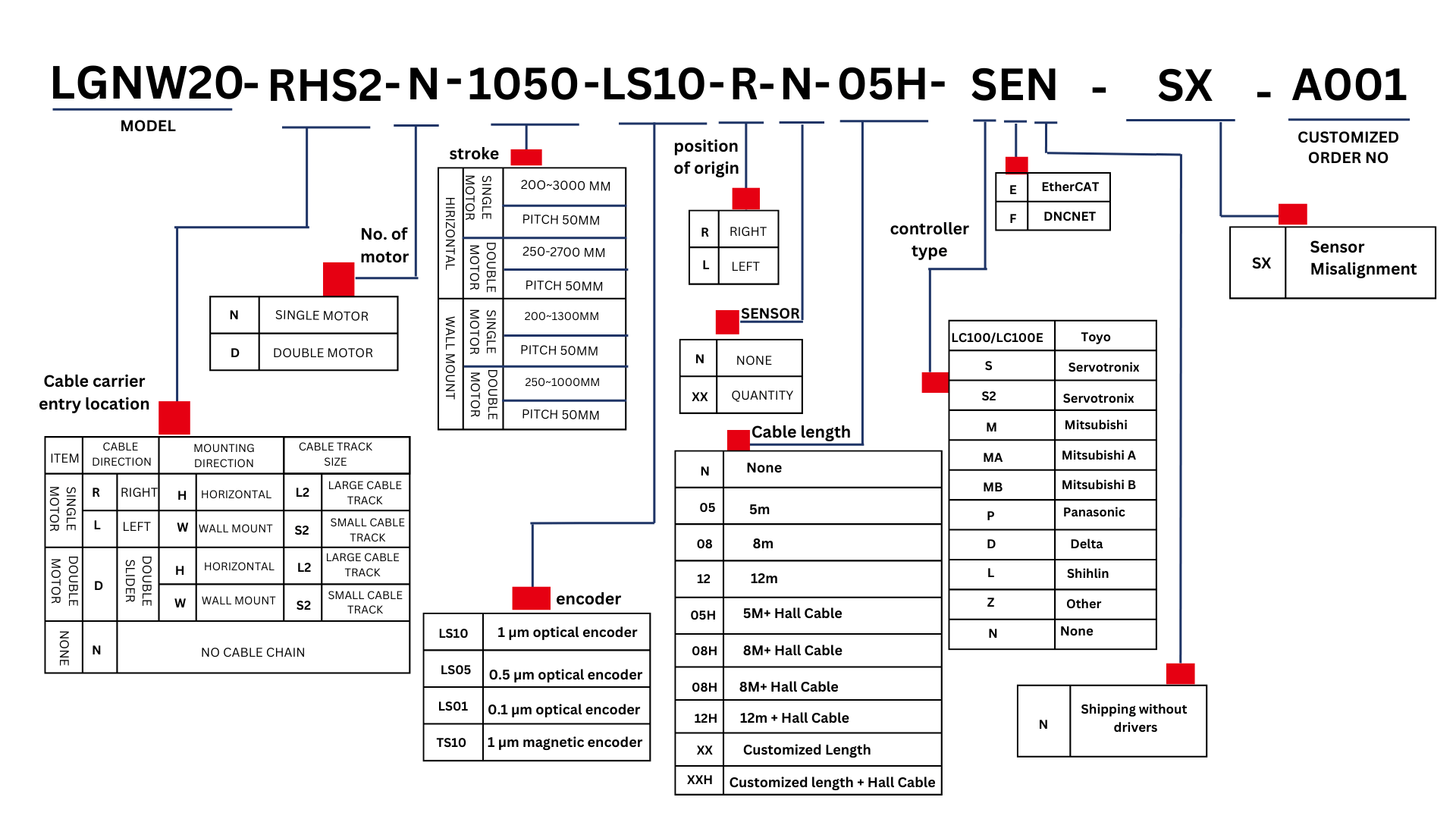

LGNW20 series

LGNW20 series specification

| Performance | Model | LGNW20 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 432 | |||

| Rated Force | N | 136.7 | |||

| Maximum Payload | Kg | 20 | 9 | ||

| Stroke | mm | 200~3000/50 pitch | 200~1300/50 pitch | ||

| mm | 250~2750/50 pitch | 250~1000/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

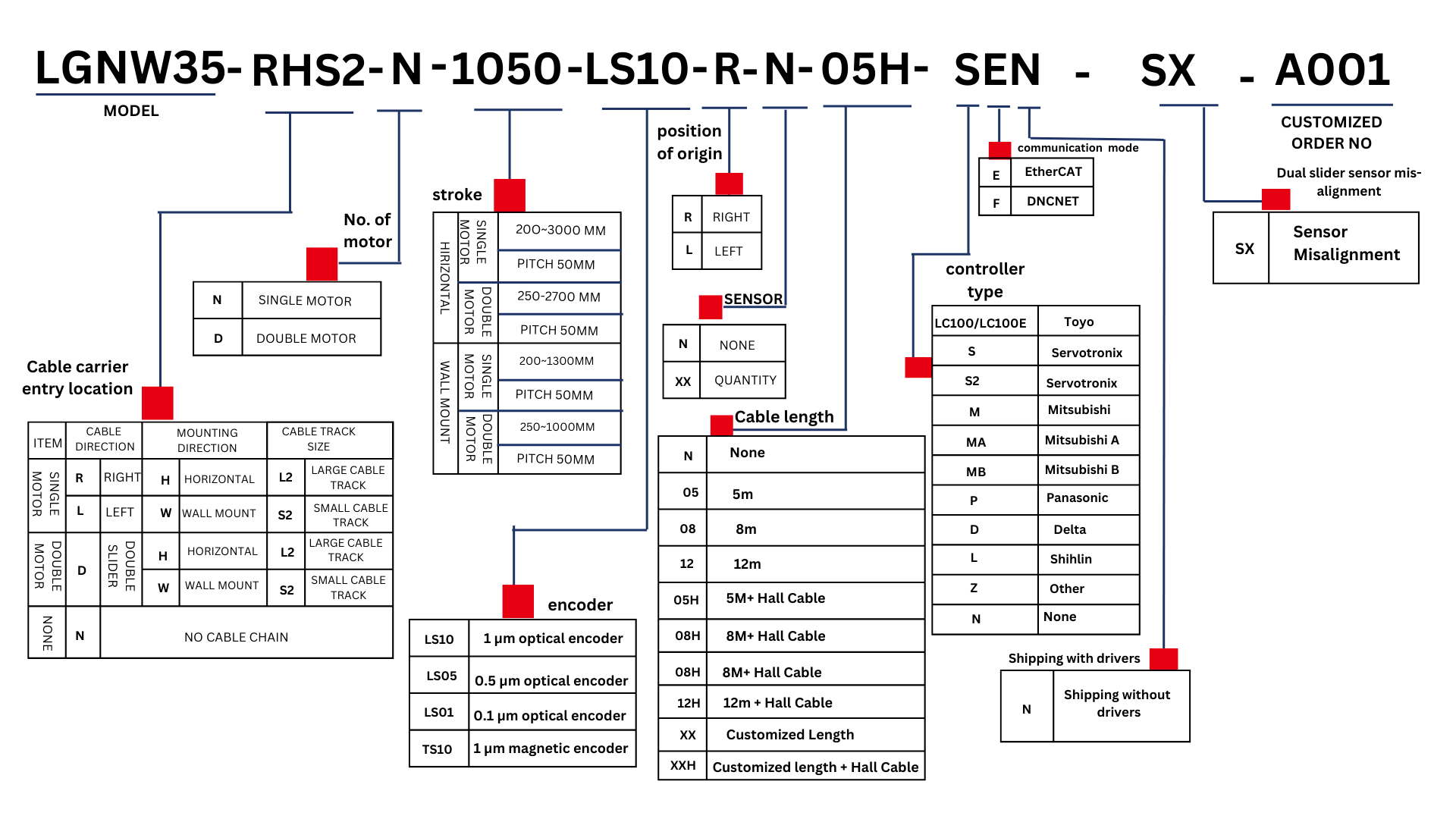

LGNW35 series

LGNW35 series specification

| Performance | Model | LGNW35 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 760 | |||

| Rated Force | N | 251 | |||

| Maximum Payload | Kg | 35 | 12 | ||

| Stroke | mm | 200~3000/50 pitch | 200~3000/50 pitch | ||

| mm | 250~2750/50 pitch | 250~2750/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

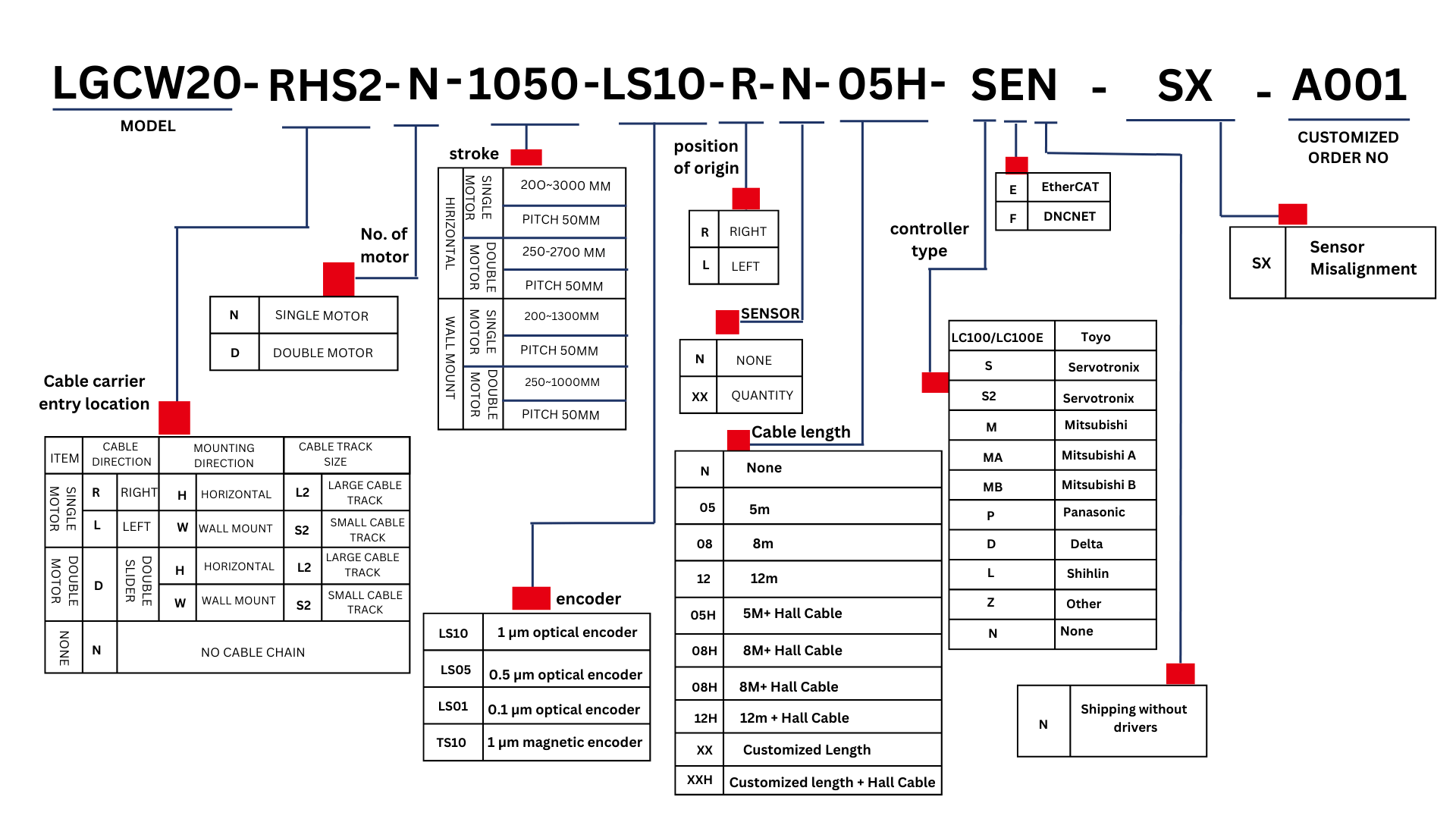

LGCW20 series

LGCW20 series specification

| Performance | Model | LGCW35 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 432 | |||

| Rated Force | N | 136.7 | |||

| Maximum Payload | Kg | 20 | 9 | ||

| Stroke | mm | 200~3000/50 pitch | 200~1300/50 pitch | ||

| mm | 250~2750/50 pitch | 250~1000/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

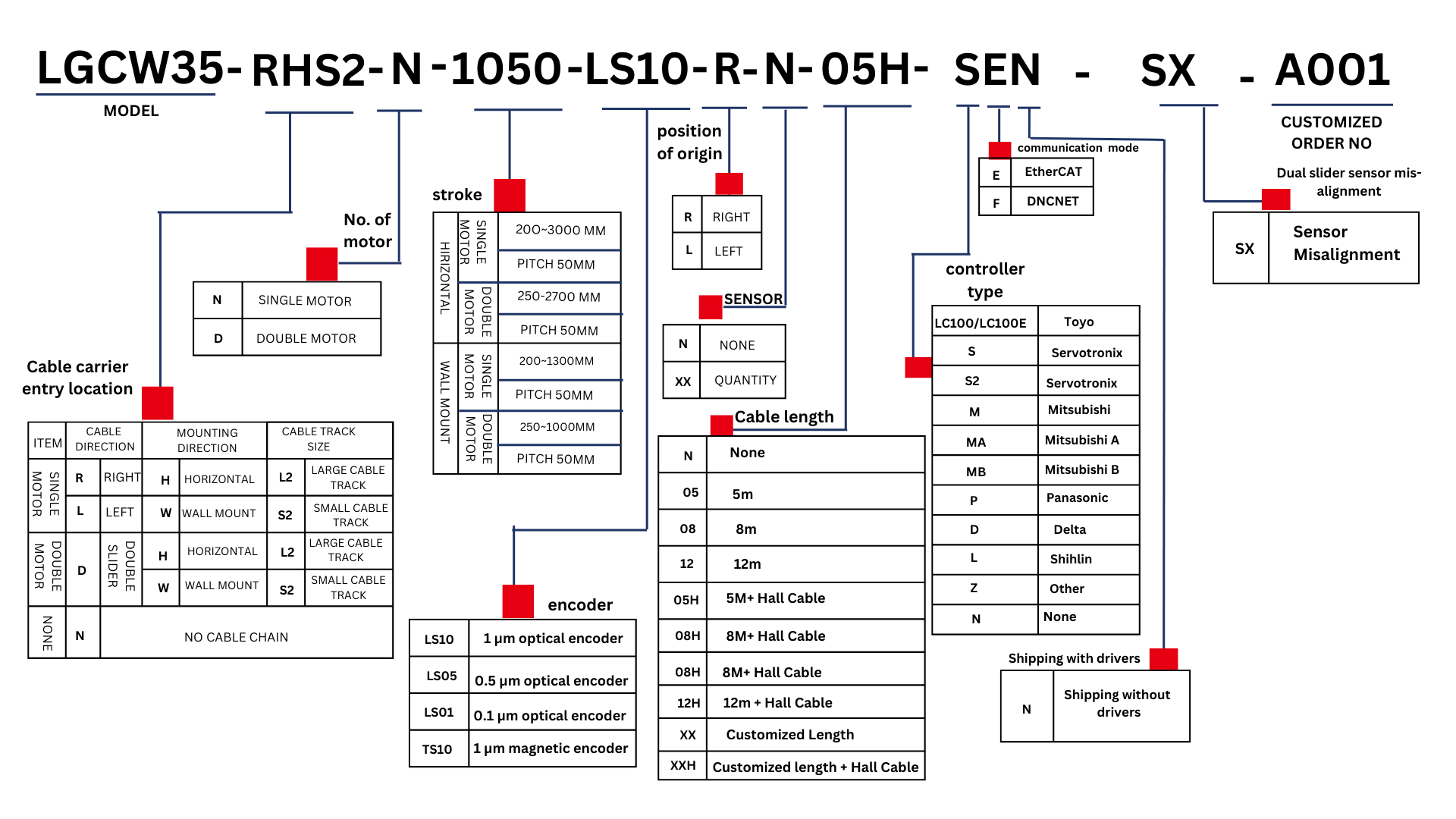

LGCW35 series

LGCW35 series specification

| Performance | Model | LGCW35 | |||

|---|---|---|---|---|---|

| Instalaltion | Horizontal | Wall Mount | |||

| Repeatability | mm | ±0.002 | |||

| Maximum Force | N | 760 | |||

| Rated Force | N | 251 | |||

| Maximum Payload | Kg | 35 | 12 | ||

| Stroke | mm | 200~3000/50 pitch | 200~1300/50 pitch | ||

| mm | 250~2750/50 pitch | 250~1000/50 pitch | |||

| Mamimum Speed | mm/s | 2500 | |||

| Parts | Brand of Linear Scale | RENISHAW | |||

| Reader | Renishaw-Q4BCX05A20E | ||||

| Origin of Z phase | Renishaw-A-9653-0143 | ||||

| Resolution of Linear Scale | 0.001 | ||||

LC100 Controller

LC100 Controller specification

| ITEM | DESCRIPTION | |

|---|---|---|

| Input Power | Control Power | Single-phase AC200 ~ 230V |

| Power Supply | Single-phase AC200 ~ 230V | |

| Number of control shaft | 1 | |

| Motor | Applicable Motor | Linear Motor |

| Rated output | 400W for 2.8A/750W for 5.6A | |

| Instantaneous maximum output | 400W for 14.2A/750W for 25A | |

| Movement control mode | ABS absolute position operation, INC relative position operation, INC-R relative position continuous operation, ABS-R absolute position continuous operation, ABS-T operation, INC-T operation, TSL torque monitoring | |

| Pulse control mode | Input control: Differential (4Mpps)/ open collector (200Kpps) signal (CW/ CCW; PULSE/DIR;A/B phase) Output signal: A, /A, B, /B, Z, /Z | |

| Position | The Total number of Points | 1~255 points (individual actions) |

| Point setting side | Communication setting point location | |

| IO point location teaching | ||

| Encoder | Location management | Incremental type |

| Position detection | AB phase PULSE maximum 10Mpps (4 times after transmission) | |

| Resolution | The resolution is determined by the reading head. The standard configuration is magnetic ruler reading head (1μm), while optional configuration is optical ruler reading head (0.5μm). | |

| General-purpose DI/DO signals | DI (15 points)/DO (15 points)NPN can be modified by parameters | |

| Error history | Up to 50 error codes can be stored | |

| Safety circuit | After emergency stop and press-in (servo OFF) | |

| Communication | USB(virtual COM port):Mini USB/RS485(half duplex):RJ11 | |

| RS-485 Modbus, can control the combined operation and direct movement of points (16 stations) | ||

| Extensible EherCAT module (255 stations) | ||

| Station numbering | Rotate the DIP switch (0~F), 16 stations | |

| Safety certification | CE, EN61800-3/EN61800-5-1 | |

| Station numbering | Rotate the DIP switch (0~F), 16 stations | |