Integrated Linear Bearings Servo Cylinder - Slider type

CGCH series of servo cylinder is a ball screw driven actuator specially designed for cleanroom applications with integrated Linear Bearings. Its maximum stroke is upto 1000mm and maximum speed is upto 600mm/s. stepper motor is provided along with it as a combine solution. TC100 series controller is used to control its movements by programming. Controller featured with Pulse control mode and EtherCAT for communication control mode.

Features

- Providing +/- 0.005 mm of repeatability

- Ball screw driven with Integrated linear bearings with slider.

- Designed for cleanroom applications.

- Maximum horizontal payload upto 30 kg.

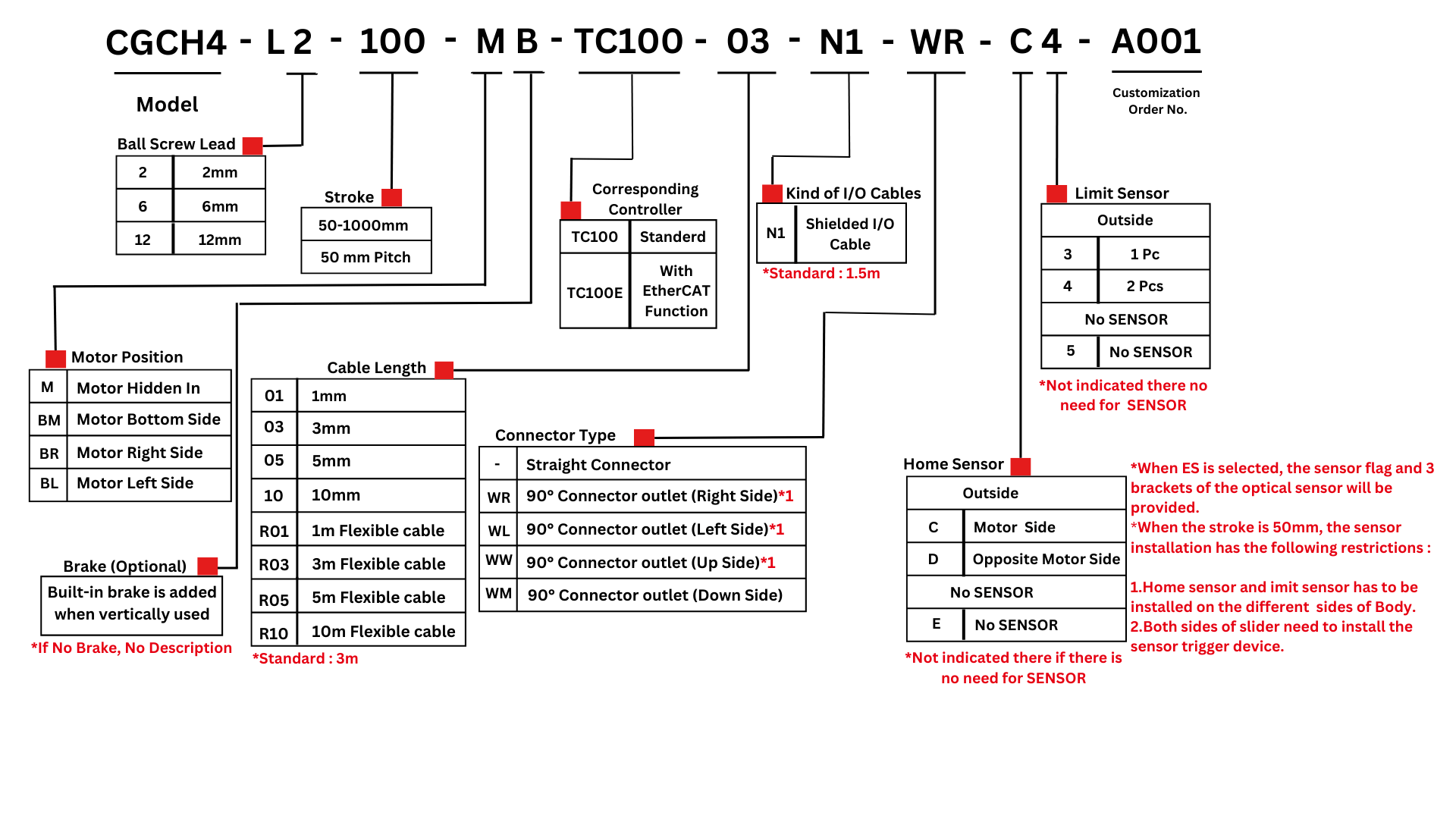

CGCH4 series

CGCH4 series specification

| Specification | Repeatability | mm | ±0.005 | |||

|---|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 6 | 12 | ||

| Minumum Rotating Speed | rpm | ≤3000 | ≤3000 | ≤3000 | ||

| Maximum Speed | Horizontal(kg) | mm/s | ≤100 | ≤300 | ≤600 | |

| Vertical(kg) | mm/s | ≤100 | ≤300 | ≤600 | ||

| Maximum Payload | Horizontal(kg) | mm/s | ≤25 | ≤20 | ≤12 | |

| Vertical(kg) | mm/s | ≤8 | ≤8 | ≤3.5 | ||

| Rated Thurst | N | 1094 | 365 | 182 | ||

| Stroke Increments | mm | 50~1000mm/50 increments | ||||

| Motor Dimension | mm | 35 | ||||

| Ball Screw Spec. | mm | C7 10mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

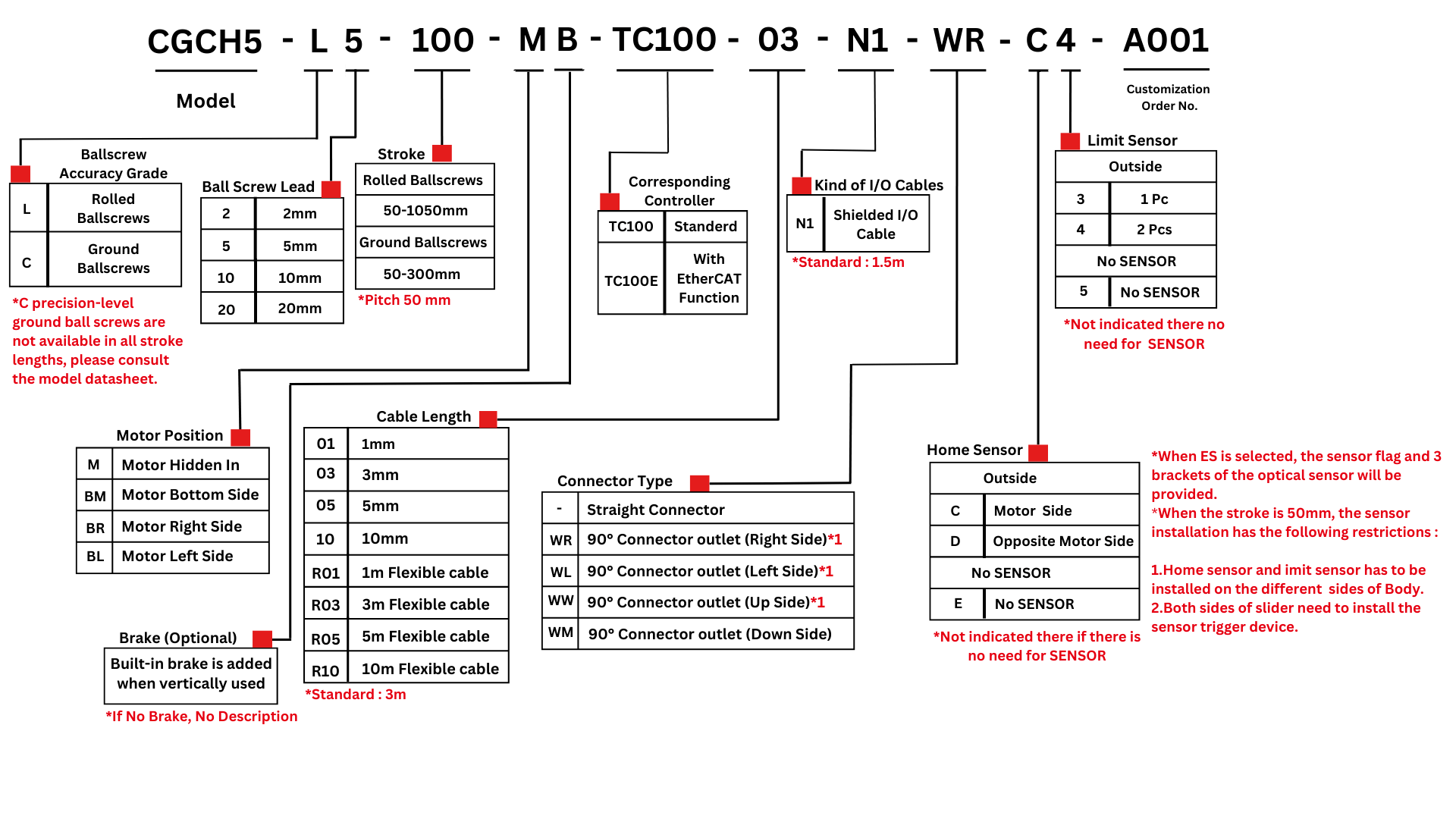

CGCH5 series

CGCH5 series specification

| Specification | Ball Screw Accuracy Grade code | L | C | |||

|---|---|---|---|---|---|---|

| Ball Screw Accuracy Grade | C7 | C5 | ||||

| Repeatability(mm) | ±0.005 | ±0.003 | ||||

| Stroke Pitch(mm) | 50~1050mm/50 increments | 50~300mm/50 increments | ||||

| Ball Screw Lead(mm) | 2 | 5 | 10 | 20 | ||

| Minumum Rotating Speed(rpm) | ≤3000 | ≤3000 | ≤3000 | ≤3000 | ||

| Maximum Speed(mm/s) | Horizontal(kg) | ≤100 | ≤250 | ≤500 | ≤1000 | |

| Vertical(kg) | ≤100 | ≤250 | ≤500 | ≤1000 | ||

| Maximum Payload(Kg) | Horizontal | ≤30 | ≤30 | ≤15 | ≤10 | |

| Vertical(kg) | ≤10 | ≤10 | ≤5 | ≤2.5 | ||

| Rated Thurst(N) | 1147 | 459 | 229 | 155 | ||

| Motor Dimension(mm) | 42 | |||||

| Ball Screw Spec. | ⌀12mm | |||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

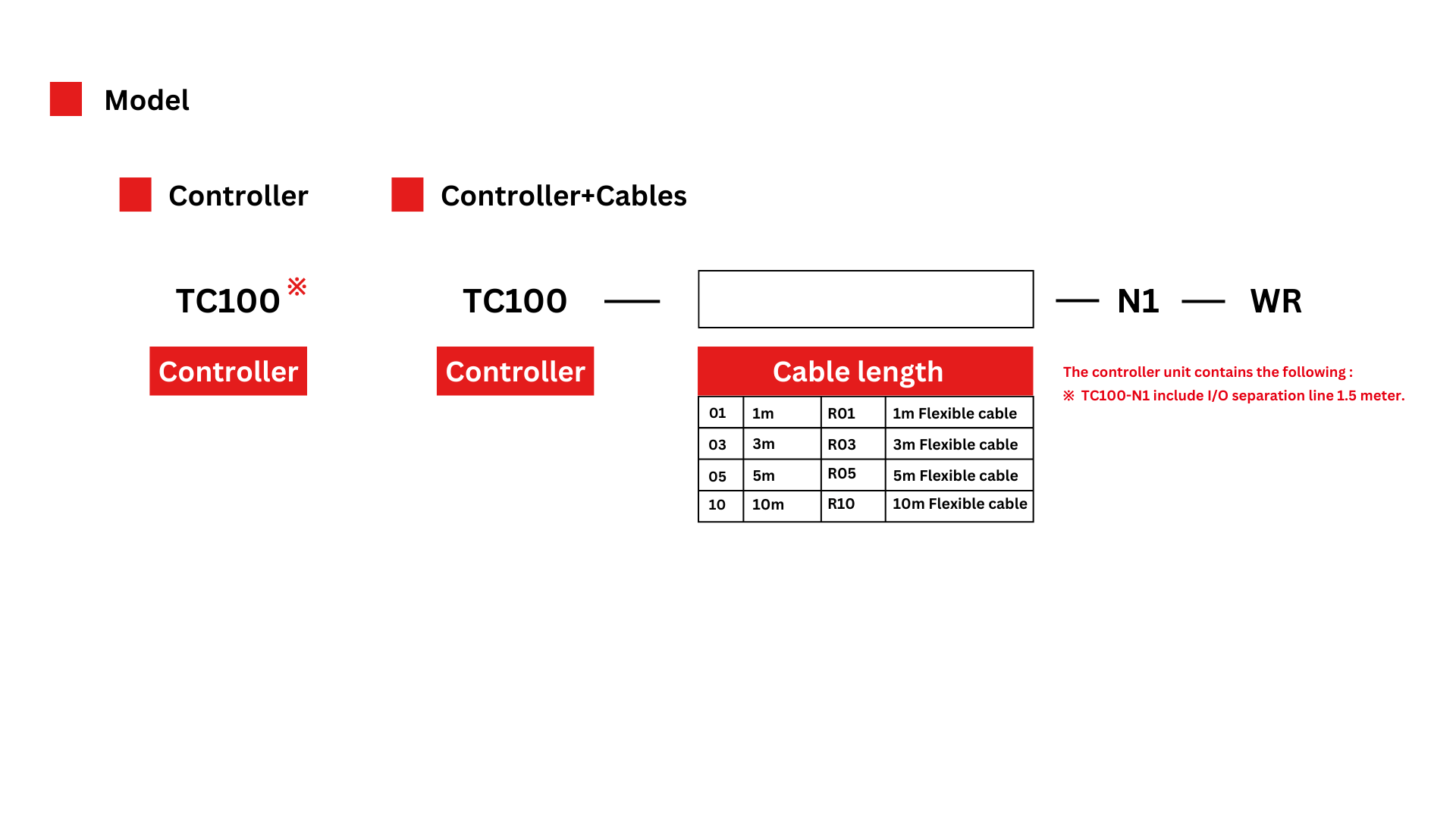

TC100

TC100 Controller specification

| ITEM | Specification | ||

|---|---|---|---|

| Input Power | Control Power | DC 24V(±10%) | |

| Power Supply | DC 24V(±10%)/DC 48V(±10%) | ||

| Number of Controlled Axis | 1 single axis | ||

| Motor | Appropriate Motor | Two phase stepping motor | |

| Dimension | 36` 42` 35` 25` 20 | ||

| Rated Output | 2Ao-p Peak value of sine wave current | ||

| Instant Maximum Output | 3Ao-p Peak value of sine wave current | ||

| Motion Control Mode | ABS Mode | ||

| INC Mode | |||

| INC-R Continuous Mode | |||

| ABS-R Continuous Mode | |||

| TSL Thurst Mode | |||

| Position | Total number of points | 1~127 points | |

| Position Setting Method | Communication setting point position | ||

| I/O point position teaching | |||

| Encoder | Position Mangement | Incremental | |

| Positiion Checking | Optical Rotary Encoder | ||

| Resolution | 16000ppr(56`42 angles)/12800ppr(35 angles)/9600ppr(25 angles)/1600ppr(20 angles) | ||

| General DI/DO Signal | DI(14 points)/DO(10 points) NPN modify definition through parameter | ||

| Brake | Optional(please inform before buying) | ||

| Error History | Maximum storage for 50 error code | ||

| Safety Circuit | Emergency stop switch(servo OFF)Emergency stop switch(servo OFF) | ||

| Communication | USB(virtual COM port):Mini USB/RS485(half duplex):RJ-45/EtherCAT | ||

| LED LED Status Desplay |

PWR: power supply(green)permanent radiating when drive + control power supply input, green flashing when the drive power supply was turned off | ||

| SON: servo(green): permanent radiating when servo ON, extingushed when the error shows | |||

| ERR: error(red); use the times of flashing to decide the error messages. | |||

| Station number setting | Rotating DIP switch (0~f), 16 station | ||