Alignment Stage

Toyo Alignment Stage is a critical component in the semiconductor industry that is used to align and position wafers accurately during the manufacturing process. The alignment stage is typically used in the front-end of the semiconductor manufacturing process, where wafers are patterned and etched. The alignment stage uses a combination of mechanical and optical techniques to ensure that the wafers are precisely aligned with the lithography equipment. The alignment stage is a critical component of the semiconductor manufacturing process, as it ensures that the wafers are accurately positioned and aligned, which is essential for producing high-quality semiconductor devices.

LXY series is a low-resistance friction design equipped with an iron core linear motor. Its appearance is light weight and has a large hollow structure design. Due to large hollow design it can be processed on both sides and placed in an optical inspection machine.

Diverse track designs such as built-in rails, crossed roller guides, and standard linear rails can be selected to support coreless rails.

Repeatability : ±0.25 μm

Speed Ripple : 300 mm/s

Plane Accuracy :±2 μm

Total Height : 44 mm

Maximum Line Speed: 1 m/s

Orthogonality : ±10 arc sec.

Features

- Precise alignment

- Large hollow design

- Multi style guide rail design

- Good dynamic performance

- Precision geometric accuracy

Applicable industries

- Panel Lamination

- Precision Printing

- Wafer Positioning

- AOI Inspection

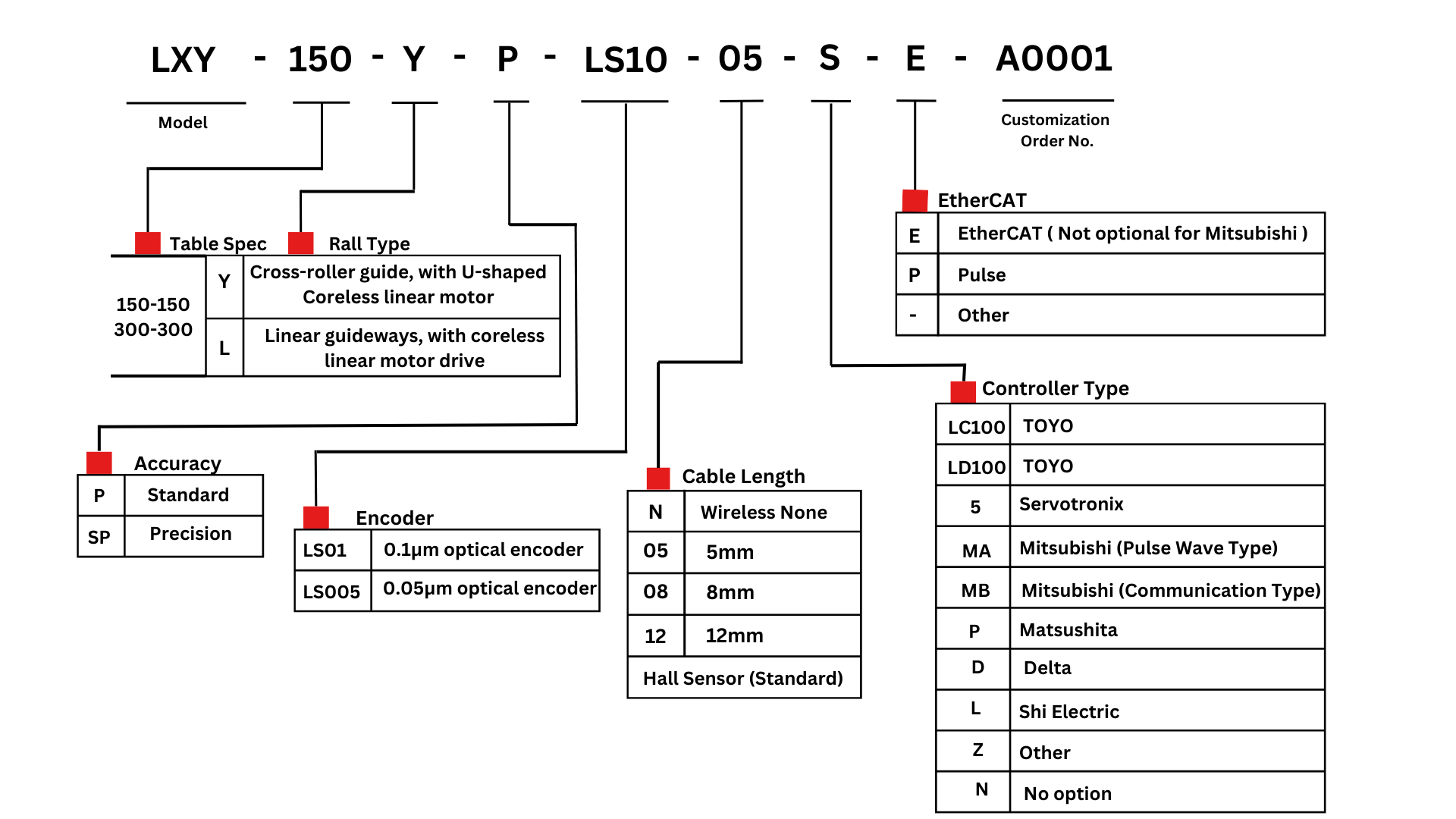

LXY-Y series

LXY-Y series specification

| Model | ||||

| Travel(mm) | ||||

| Accuracy(μm) | ||||

| Repeatability(μm) | ||||

| Straightness(μm) | ||||

| Flatness(μm) | ||||

| Maximum Speed(mm/s) | ||||

| Continuous Force(N) | ||||

| Peek Force(N) | ||||

| Load Capacity(kg) | ||||

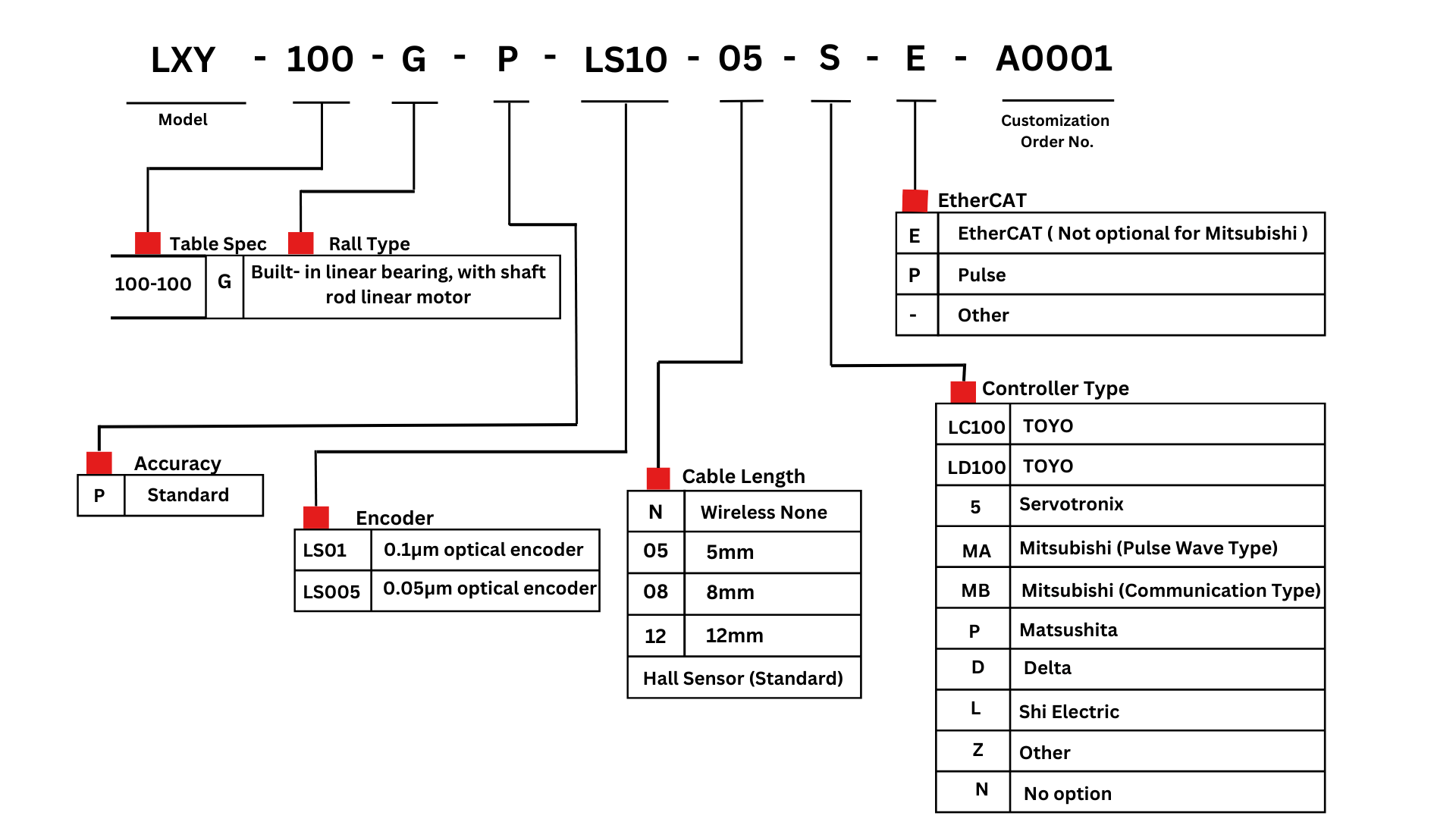

LXY-G series

LXY-G series specification

| Model | |

| Travel(mm) | |

| Accuracy(μm) | |

| Repeatability(μm) | |

| Straightness(μm) | |

| Flatness(μm) | |

| Maximum Speed(m/s) | |

| Maximum acceleration(m/s2) | |

| Continuous Force(N) | |

| Peek Force(N) | |

| Load Capacity(kg) |