Mini Cylinder

Toyo’s Actuator with Motor CSG series is used in different applications where high rigidity is required. It is intended to offer extremely precise and accurate control and placement of large loads. The cylinder has a robust and dependable design that can tolerate challenging operating circumstances, together with a high-quality servo valve that enables precise control over the cylinder's movement. In sectors where accurate and dependable placement is essential, like manufacturing, aerospace, and automotive, the Toyo Actuator with Motor CSG series is extensively utilized.

The utilization of a ball screw driven mini cylinder offers precise linear motion in compact spaces, making it a versatile solution across various industries.

Features

- The ball screw driven mini cylinder incorporates a small form factor, making it suitable for applications with limited space constraints.

- Utilizes a ball screw mechanism to achieve accurate and repeatable linear motion, ensuring precise positioning and control.

- The ball screw design minimizes friction and backlash, contributing to smooth and consistent movement with minimal play.

- Despite its small size, the ball screw driven mini cylinder can support significant loads, making it suitable for various industrial applications.

Applications

Micro-positioning systems, Miniature robotics, Optical and photonics, Medical devices, Automated optical inspection (AOI) systems, Micro-manipulation and Micro-assembly, Miniature actuated grippers and End effectors

Industries

Industrial robot Industry, TFT display manufacturing, Semi-conductor manufacturing, LED manufacturing, Material handling industry, Lab automation, Nanotechnology

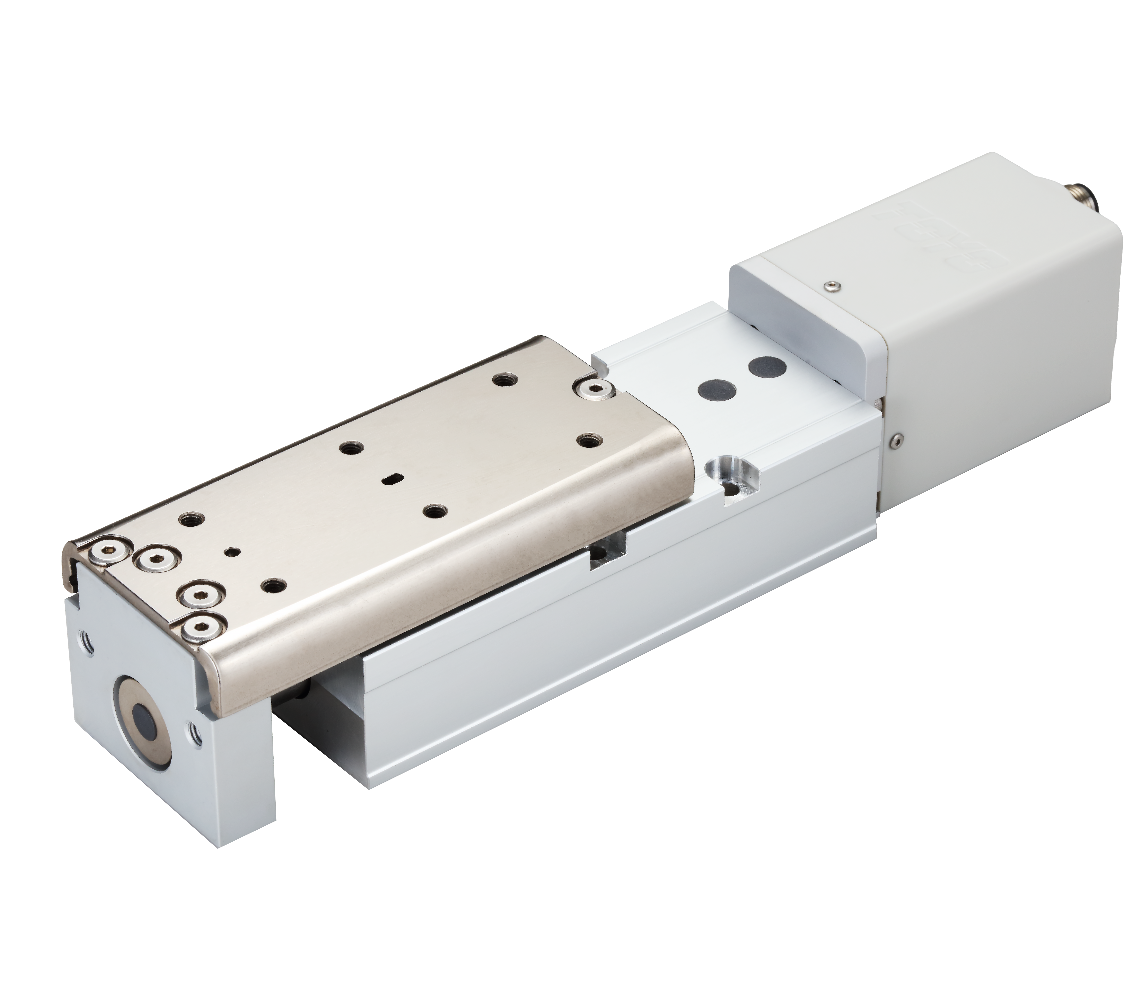

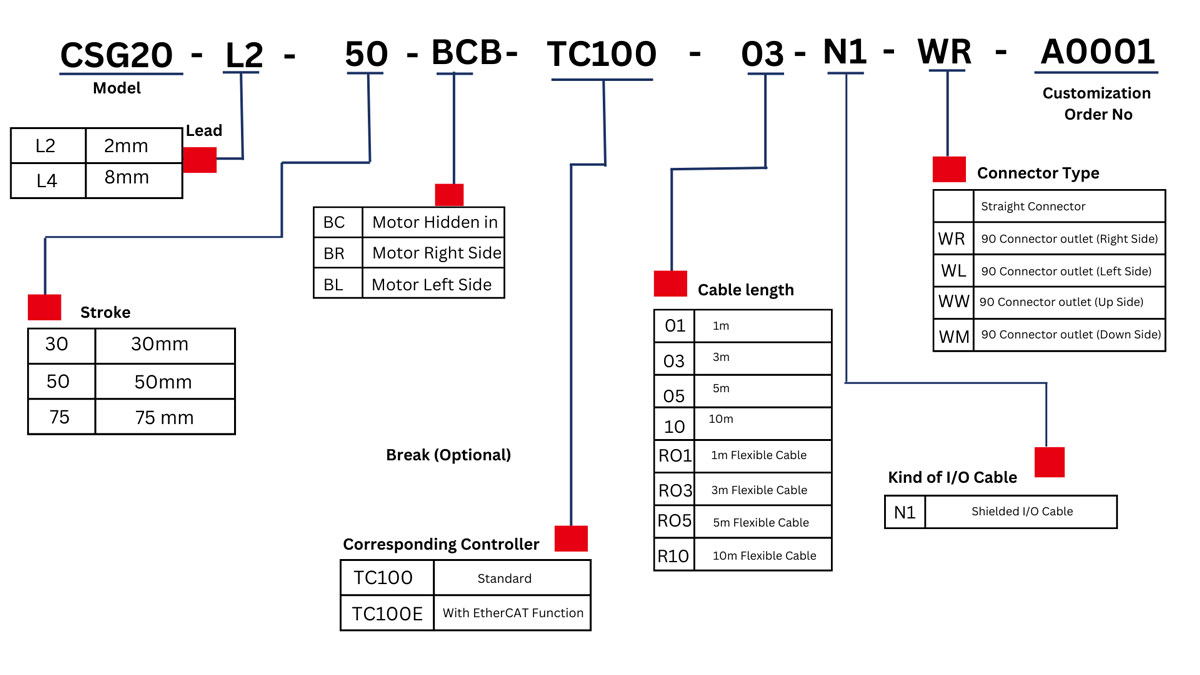

CSG-20 series

CSG-20 series specification

| Specification | Repeatability (mm) | +/-0.01 | ||

|---|---|---|---|---|

| Ball Screw Lead (mm) | 2 | 4 | ||

| Maximum Speed | ||||

| Horizontal (kg) | 83.3 | 166.6 | ||

| Vertical (kg) | 83.3 | 166.6 | ||

| Maximum Payload | Horizontal (kg) | 3 | 1.5 | |

| Vertical (kg) | 2.5 | 1 | ||

| Rated Thrust (N) | 30 | 16 | ||

| Stroke (increments) (mm) | 30/50/75 | |||

| Parts | Motor Dimension (mm) | 20□ | ||

| Ball Screw Spec | C10 Φ6mm | |||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

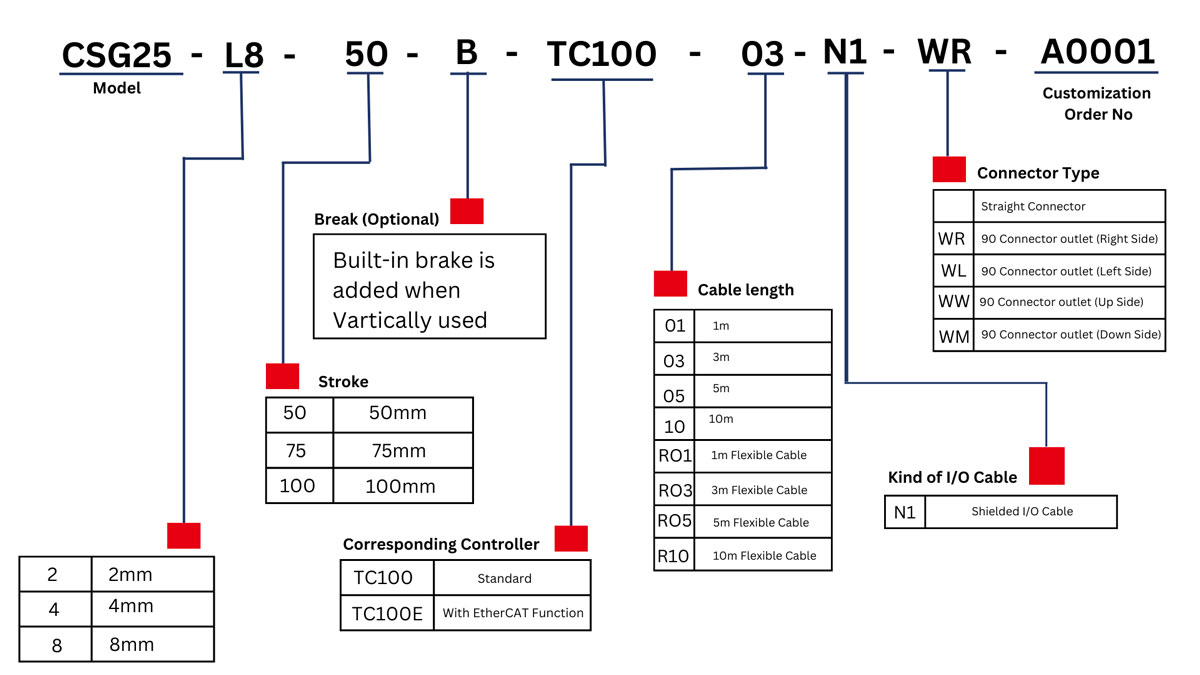

CSG-25 series

CSG-25 series specification

| Specification | Repeatability | mm | +/-0.01 | ||

|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 4 | 8 | |

| Acceleration | G | 0.1 | 0.1 | 0.3 | |

| Maximum Speed mm/s | |||||

| Horizontal (kg) | 100 | 200 | 400 | ||

| Vertical (kg) | 100 | 200 | 260 | ||

| Maximum Payload" | Horizontal (kg) | 9.6 | 7.4 | 2.4 | |

| Vertical (kg) | 5 | 1.6 | 0.41 | ||

| Rated Thrust (N) | 135 | 68 | 34 | ||

| Stroke (increments) (mm) | 50/75/100 | ||||

| Parts | Motor Dimension (mm) | 25□ | |||

| Ball Screw Spec | C10 Φ6mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

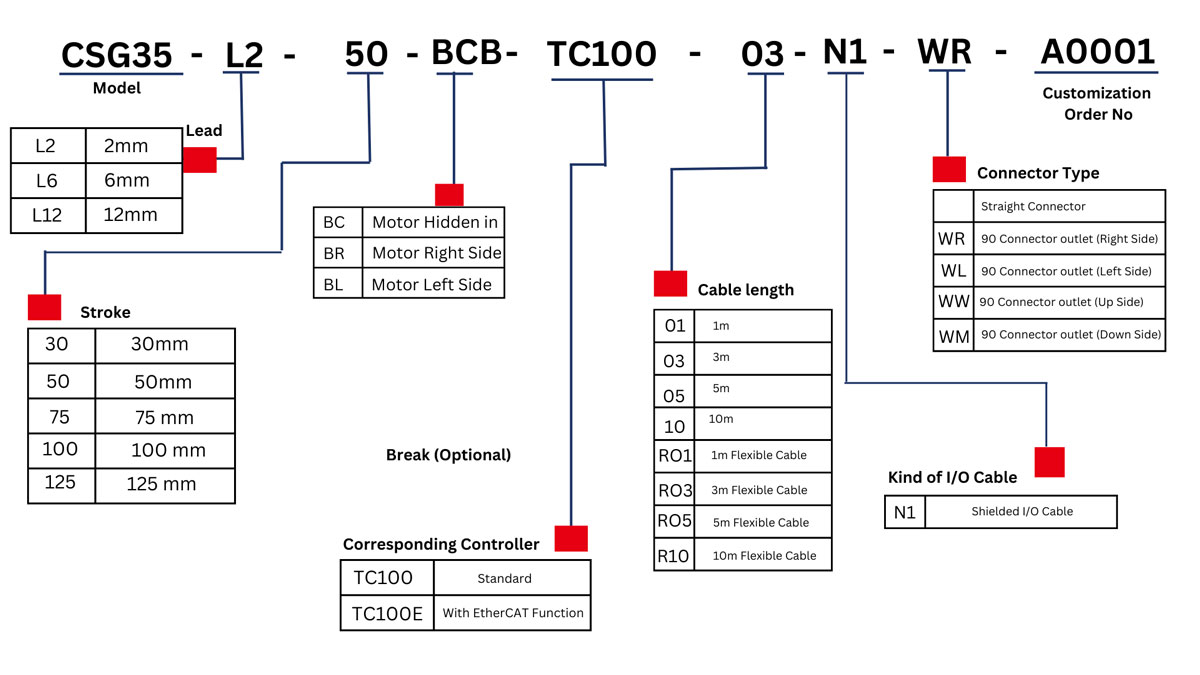

CSG-35 series

CSG-35 series specification

| Specification | Repeatability (mm) | mm | +/-0.01 | ||

|---|---|---|---|---|---|

| Acceleration(G) | G | 0.1 | 0.3 | 0.3 | |

| Ball Screw Lead (mm) | mm | 2 | 6 | 12 | |

| Maximum Speed | |||||

| Horizontal (kg) | 100 | 300 | 600 | ||

| Vertical (kg) | 100 | 300 | 600 | ||

| Maximum Payload | Horizontal (kg) | 12.8 | 8.4 | 5.2 | |

| Vertical (kg) | 6.4 | 3.2 | 1.2 | ||

| Rated Thrust (N) | 440 | 150 | 75 | ||

| Stroke (increments) (mm) | 30/50/75/100/125 | ||||

| Parts | Motor Dimension (mm) | 35□ | |||

| Ball Screw Spec | C10 Φ10mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

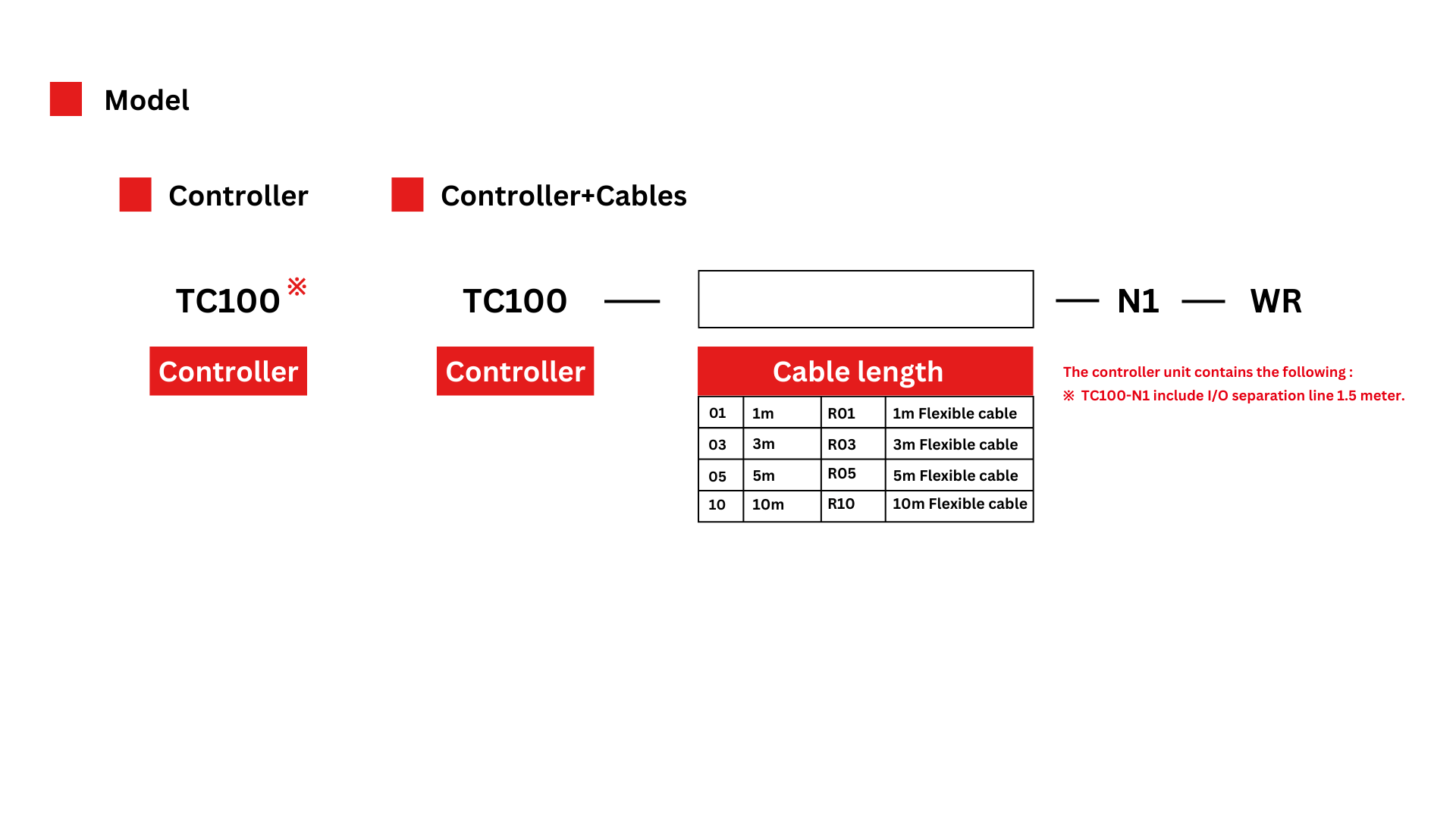

TC100

TC100 Controller specification

| ITEM | Specification | ||

|---|---|---|---|

| Input Power | Control Power | DC 24V(±10%) | |

| Power Supply | DC 24V(±10%)/DC 48V(±10%) | ||

| Number of Controlled Axis | 1 single axis | ||

| Motor | Appropriate Motor | Two phase stepping motor | |

| Dimension | 36` 42` 35` 25` 20 | ||

| Rated Output | 2Ao-p Peak value of sine wave current | ||

| Instant Maximum Output | 3Ao-p Peak value of sine wave current | ||

| Motion Control Mode | ABS Mode | ||

| INC Mode | |||

| INC-R Continuous Mode | |||

| ABS-R Continuous Mode | |||

| TSL Thurst Mode | |||

| Position | Total number of points | 1~127 points | |

| Position Setting Method | Communication setting point position | ||

| I/O point position teaching | |||

| Encoder | Position Mangement | Incremental | |

| Positiion Checking | Optical Rotary Encoder | ||

| Resolution | 16000ppr(56`42 angles)/12800ppr(35 angles)/9600ppr(25 angles)/1600ppr(20 angles) | ||

| General DI/DO Signal | DI(14 points)/DO(10 points) NPN modify definition through parameter | ||

| Brake | Optional(please inform before buying) | ||

| Error History | Maximum storage for 50 error code | ||

| Safety Circuit | Emergency stop switch(servo OFF)Emergency stop switch(servo OFF) | ||

| Communication | USB(virtual COM port):Mini USB/RS485(half duplex):RJ-45/EtherCAT | ||

| LED LED Status Desplay |

PWR: power supply(green)permanent radiating when drive + control power supply input, green flashing when the drive power supply was turned off | ||

| SON: servo(green): permanent radiating when servo ON, extingushed when the error shows | |||

| ERR: error(red); use the times of flashing to decide the error messages. | |||

| Station number setting | Rotating DIP switch (0~f), 16 station | ||