Linear Actuator with Motor- Rod Type

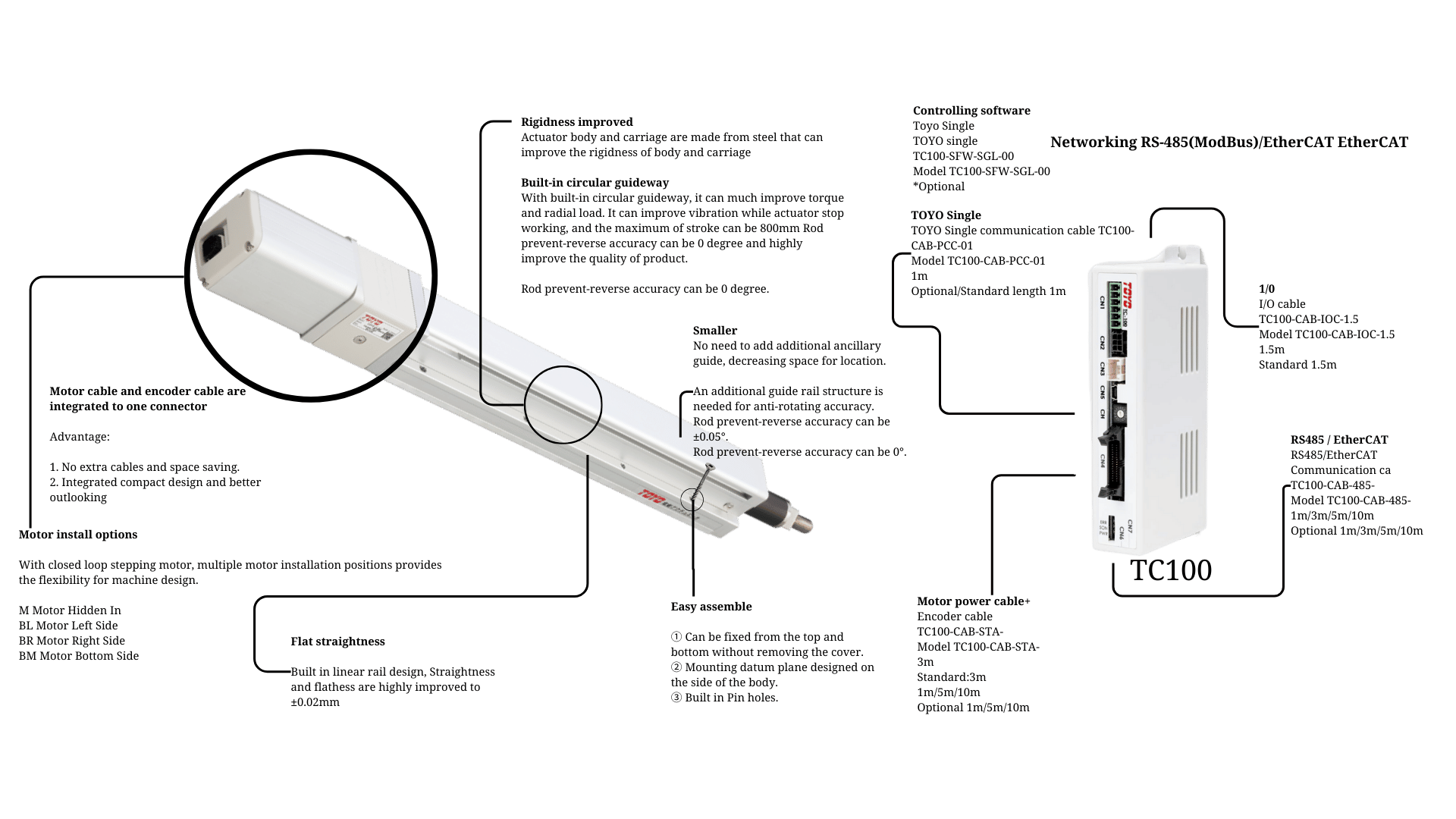

Servo cylinder or servo actuator is a type of double-acting cylinder used in mechatronic system. Common rod types actuator includes ball screws, which are known for their higher efficiency and precision, making them ideal for applications where accurate positioning is crucial.

CGTY Series is integrated with linear bearings, comes with stepper motor solution. These actuators combine the motor and actuator into a single unit, simplifying installation and reducing overall system complexity.

By utilizing our TC100 series controller with an electric actuator, users can achieve enhanced performance, flexibility, and automation capabilities in their systems. It allows for more sophisticated control strategies, integrates easily with other automation components, and ensures reliable and precise operation of the electric actuator in diverse applications.

Features

- Improved precision and accuracy in motion control by continuously monitoring and correcting the motor's position through a feedback system, often involving encoders.

- Increased reliability as the feedback mechanism continuously detects and corrects errors, ensuring consistent performance.

- Closed loop stepper motor actuators adjust power consumption based on actual load requirements which contributes to overall energy savings.

- Standard controller (TC100) provides PULSE, communication and other two control interfaces and can be equipped with CAN Open and EtherCAT networks.

- Low noise and easy maintenance.

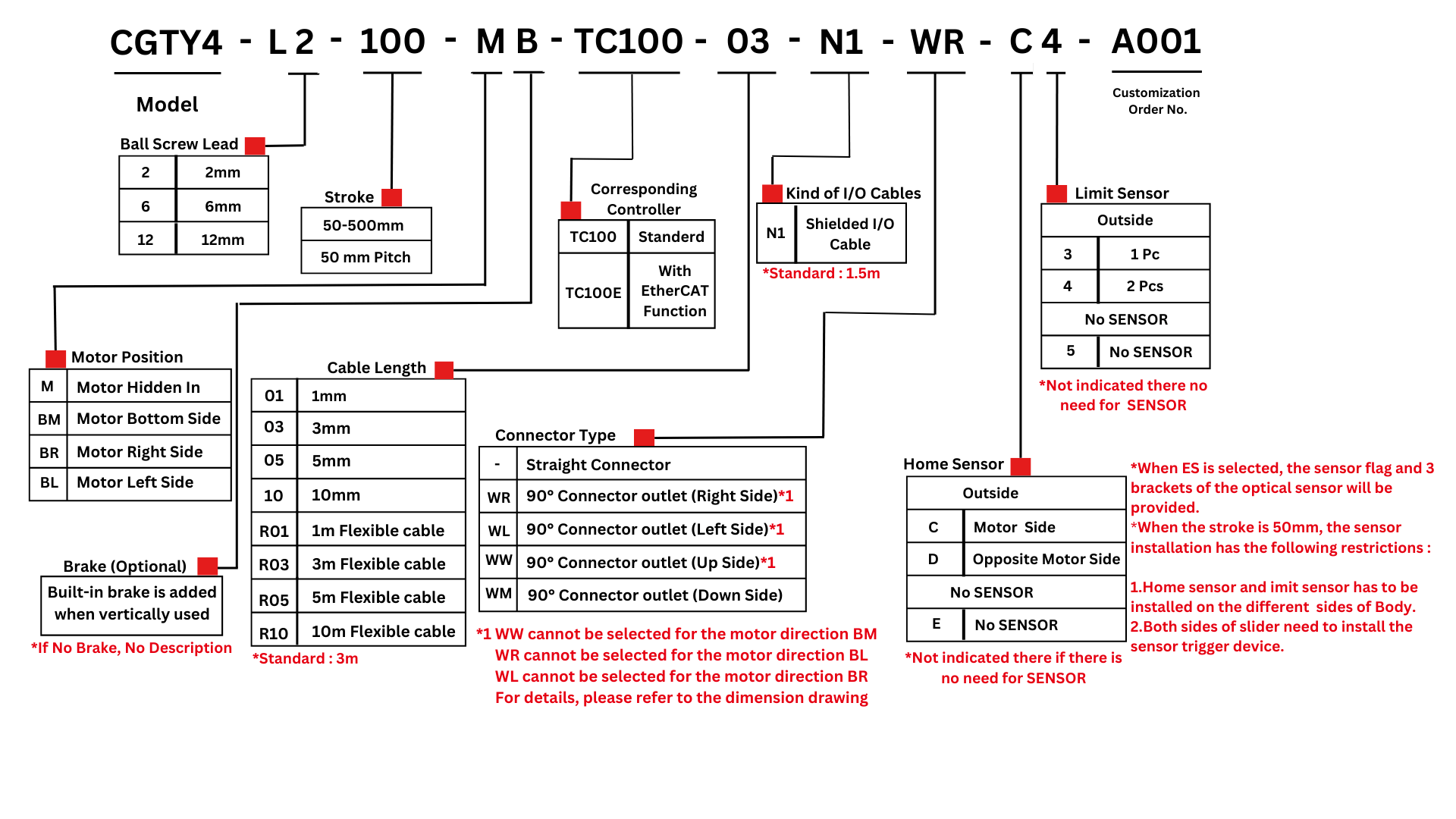

CGTY4 series

CGTY4 series specification

| Specification | Repeatability | mm | ±0.01 | |||

|---|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 6 | 12 | ||

| Minumum Rotating Speed | rpm | ≤3000 | ≤3000 | ≤3000 | ||

| Maximum Speed | Horizontal(kg) | mm/s | ≤100 | ≤300 | ≤600 | |

| Vertical(kg) | mm/s | ≤100 | ≤300 | ≤600 | ||

| Maximum Payload | Horizontal(kg) | Kg | ≤25 | ≤20 | ≤12 | |

| Vertical(kg) | Kg | ≤8 | ≤8 | ≤3.5 | ||

| Rated Thurst | N | 1094 | 365 | 182 | ||

| Stroke Increments | mm | 50-500mm/50 increments | ||||

| Motor Dimension | mm | 35 | ||||

| Ball Screw Spec. | mm | C7 ⌀ 10mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

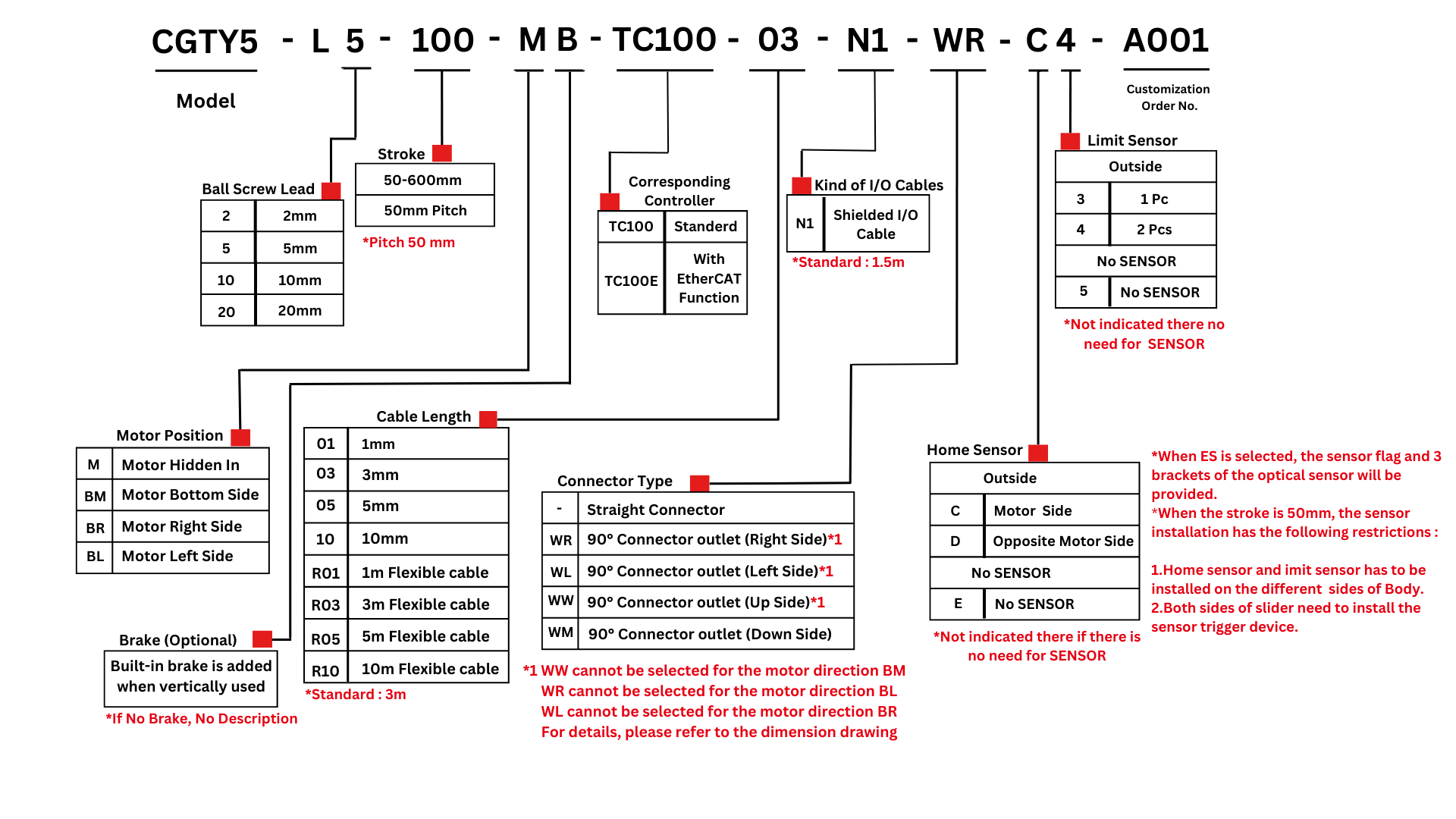

CGTH5 series

CGTY5 series specification

| Specification | Repeatability | mm | ±0.01 | |||

|---|---|---|---|---|---|---|

| Ball Screw Lead | mm | 2 | 5 | 10 | 20 | |

| Minumum Rotating Speed | rpm | ≤3000 | ≤3000 | ≤3000 | ≤3000 | |

| Maximum Speed | Horizontal(kg) | mm/s | ≤100 | ≤250 | ≤500 | ≤1000 |

| Vertical(kg) | mm/s | ≤100 | ≤250 | ≤500 | ≤1000 | |

| Maximum Payload | Horizontal | (kg) | ≤30 | ≤30 | ≤15 | ≤10 |

| Vertical | kg | ≤10 | ≤10 | ≤5 | ≤2.5 | |

| Rated Thurst | N | 1047 | 459 | 229 | 115 | |

| Stroke Increments | mm | 50-600mm/50 increments | ||||

| Motor Dimension | mm | 35 | ||||

| Ball Screw Spec. | mm | C7 ⌀12 mm | ||||

| Corresponding Controller Chart | |||

|---|---|---|---|

| Controller Model | Features | Electrical Spec. | |

| TC100 | Pulse Control Mode | Line driver 200k Hz/Open Collector 60k Hz support line driver and open collector Max. pulse receiving speed 200k/60k Hz. |

The voltage of control circuit is 24V only. Operating voltage DC24V, rated current 2A, peak current 3A. Operating voltage:DC48V, rated current 1A, peak current 2A. when the voltage is DC48V but same torque, the rotation speed will be raised. |

| I/O Control Mode | By I/O control, max. 127 positioning points, can be executed | ||

| Communication Control Mode | With Modbus RS-485 or EtherCAT (connect over 16 axes in series) and USB module |

||

| (Optional)with EterCAT, connect over 16 axes can be in series | |||

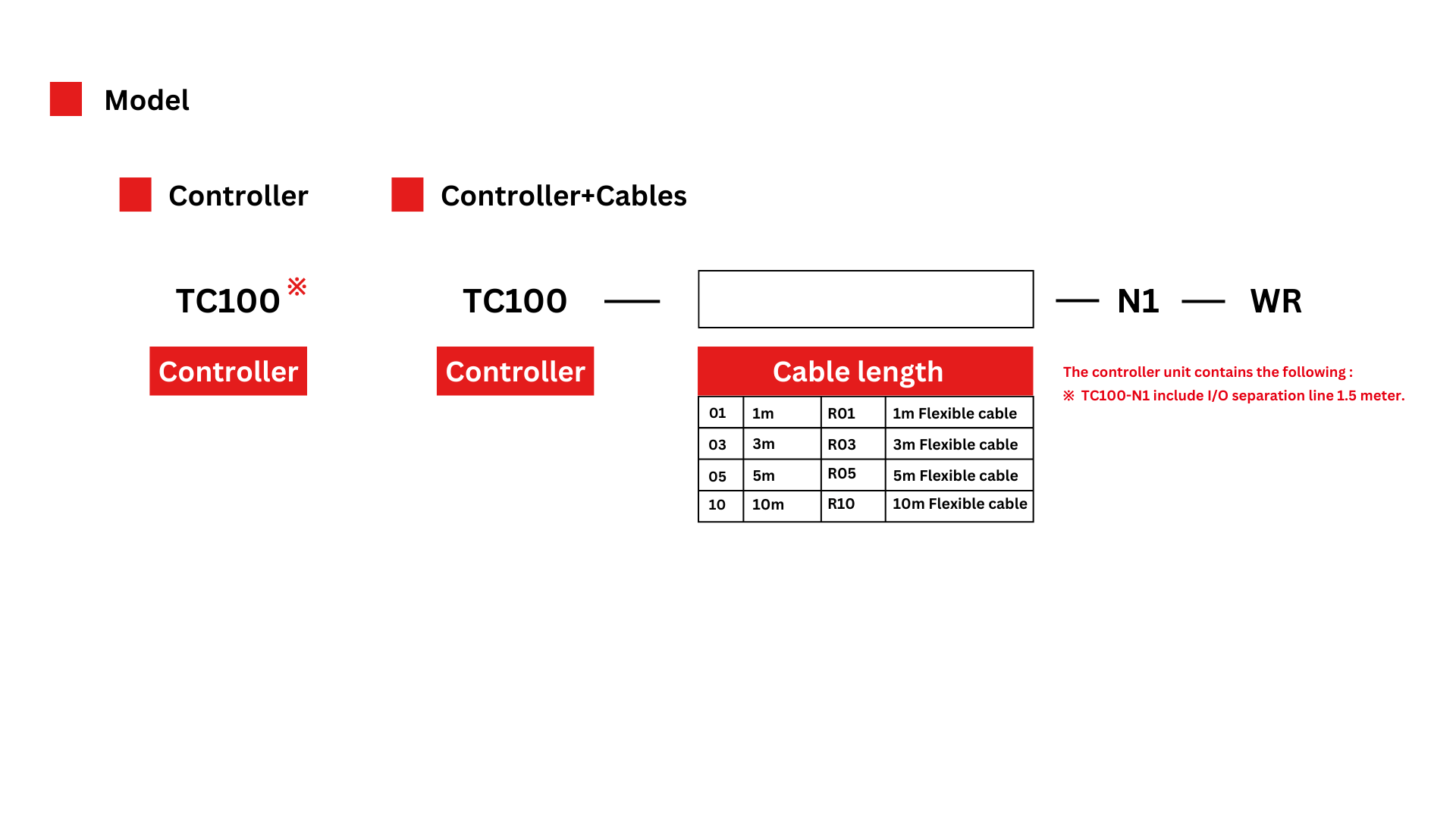

TC100

TC100 Controller specification

| ITEM | Specification | ||

|---|---|---|---|

| Input Power | Control Power | DC 24V(±10%) | |

| Power Supply | DC 24V(±10%)/DC 48V(±10%) | ||

| Number of Controlled Axis | 1 single axis | ||

| Motor | Appropriate Motor | Two phase stepping motor | |

| Dimension | 36` 42` 35` 25` 20 | ||

| Rated Output | 2Ao-p Peak value of sine wave current | ||

| Instant Maximum Output | 3Ao-p Peak value of sine wave current | ||

| Motion Control Mode | ABS Mode | ||

| INC Mode | |||

| INC-R Continuous Mode | |||

| ABS-R Continuous Mode | |||

| TSL Thurst Mode | |||

| Position | Total number of points | 1~127 points | |

| Position Setting Method | Communication setting point position | ||

| I/O point position teaching | |||

| Encoder | Position Mangement | Incremental | |

| Positiion Checking | Optical Rotary Encoder | ||

| Resolution | 16000ppr(56`42 angles)/12800ppr(35 angles)/9600ppr(25 angles)/1600ppr(20 angles) | ||

| General DI/DO Signal | DI(14 points)/DO(10 points) NPN modify definition through parameter | ||

| Brake | Optional(please inform before buying) | ||

| Error History | Maximum storage for 50 error code | ||

| Safety Circuit | Emergency stop switch(servo OFF)Emergency stop switch(servo OFF) | ||

| Communication | USB(virtual COM port):Mini USB/RS485(half duplex):RJ-45/EtherCAT | ||

| LED LED Status Desplay |

PWR: power supply(green)permanent radiating when drive + control power supply input, green flashing when the drive power supply was turned off | ||

| SON: servo(green): permanent radiating when servo ON, extingushed when the error shows | |||

| ERR: error(red); use the times of flashing to decide the error messages. | |||

| Station number setting | Rotating DIP switch (0~f), 16 station | ||